Quick Inquiry

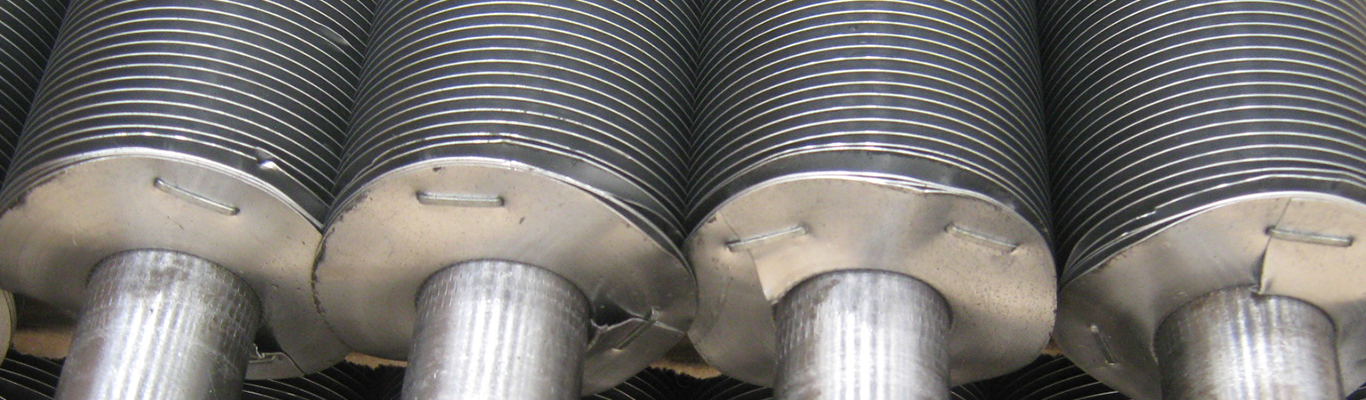

Finned tubes serve as heat exchangers that generally use air to cool or heat fluids such as water and oil. These mechanical tubes are used across industries in diesel charge air coolers, oil coolers, hydrogen coolers, waste heat recovery, driers, air conditioning, air heaters, generator coolers, and steam condensers.

Heat exchanger tubes come in different heights, designs, and materials. Here is a list of the different kinds of finned tubes to help you understand which one to pick for varied functions:

Elfin Finned Tubes

Elfin finned tubes have found takers and wide-scale usage in hydropower generator coolers. They are typically used to cool the generator used in these stations. In an Elfin tube, the fin strip is mechanically forced on the outer side to ensure adhesion of the fin to the heat exchanger tube.

Bulleted Fins

Bulleted fins are similar to Elfin tubes and have become popular as a convenient and cost-effective method to attach strip fins to tubes. They are manufactured by manually placing fins over the tubes and pushing and pulling a bullet through the tube to expand the tube wall out into the fins.

L Finned Tubes

The L finned mechanical tube receives its name from the letter L, which it creates from the cross-sectional view. L finned tubes maximize the heat transfer capacity and enhance corrosion protection. These heat exchanger tubes accommodate temperatures between 150 to 170 degrees. They come in ductile metals, such as aluminum or copper, that can withstand the compression around the fin’s base.

LL Finned Tubes

LL finned tubes are manufactured in the same way the L fins. However, they have LL fins that have overlapping feet and completely enclose the base tube. As a result, they are more resistant to corrosion. These heat exchanger tubes usually are available in copper and aluminum and have a maximum operating temperature similar to that of L finned tubes.

KL Finned Tubes

The KL in the name of this category of tubes stands for Knurled Finned. The fin in these tubes is wrapped around the tube and the foot is rolled out into the outer surface of the pre-knurled tube and secured at each end. These fins are made of thin strips of metal, machined into an L-shaped foot.

G Embedded Finned Tube

The G embedded finned tube has a unique design feature wherein the fin is inserted and welded into a helical groove cut into the tubes. These mechanical tubes are perfect for higher temperatures. They are durable and best suited for high thermal cycling because they can withstand temperatures up to 400 degrees.

Extruded Finned Tube

Two metals are used to manufacture extruded finned tubes. The outer surface is usually aluminum, while the inner tube is of any material. These heat exchanger tubes are quite popular because they offer excellent corrosion protection of the base tube. Also, they exclude all exposure to any outside fluid. Extruded finned tubes have found application in heat pipes, dry air coolers, energy recovery in the air exhaust system, etc.

Wire Finned Tube

The wire loop tube offers excellent heat transfer because it promotes turbulence in the fluid passing over it. These tubes consist of an elongated wire loop that increases the surface. The loops are spirally wound onto the top of the tube wall and fixed using a binding wire at the loop’s base. These tubes can withstand temperatures of up to 250 degrees.

Need expert advice? You can connect with Anand Seamless Ltd – one of the most reputable tube manufacturers in India!

Reach Out to Industry Experts!

Let us help you find the best quality mechanical tubes. Anand Seamless Ltd, a leading finned tube manufacturer, offers a wide range of products for the boiler industry. From high-quality seamless pipes to hydraulic tubes and finned tubes to mechanical tubes, we have a huge range of products. To know more, you can call us at +91-9099996851 or send your queries to inquiry@anandseamless.com.

lATEST BLOG |

|

How to Select the Right SA 179 Seamless Tube For Your Project?

Choosing the right SA 179 seamless tube for your p |

|

An Introductory Guide to Understanding Evaporator Tubes

Evaporator tubes are crucial components in various |

|

Guide to Maintaining Steam Coil Heater Tubes in HVAC Systems

Steam coil heater tubes are integral to the effici |

|

Carbon Steel Tubes: Essential Components in Shipbuilding

Selecting the right materials is of utmost importa |

|

How to Choose Right Grade Carbon Steel Seamless Tubes

Carbon steel seamless tubes are essential componen |