Crimped Fin Tube (Spiral Tension...

read moreGROOVED FIN TUBE OR ‘G’ FIN TUBE (EMBEDDED FIN TUBE ):-

The ‘G FIN TUBE is also known as Embedded Fin Tube. This type of fin tube widely finds acceptance where the requirement is for higher operating temperature and relatively lower corrosive atmosphere

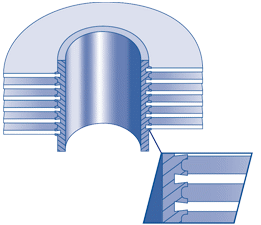

The fins are manufactured by embedding the fin strip into a groove formed on the base tube. The Fin is allowed to be placed in the groove and then the backfilling of the groove is carried out to ensure firm adherence of the fins to the base tubes. Because of the process this type of Fin Tube is also known as ‘G’ Fin tube or Grooved Fin Tube.

The grooving, fin stack inserting and the backfilling processes are carried put simultaneously as continuous operation. Because of the back filling procedure the bond between the Fin material and the Base tube is one of the best. This ensures optimum Heat Transfer.

These Fin Tubes find application in AIR FIN COOLERS, RADIATORS etc. and are preferred in Industries like Power Plants, Chemical Industries, Petroleum Refineries, Chemical process Plants, and Rubber Plants etc.

Properties of ‘G’ Fin Tubes or Grooved Fin Tubes (Embedded Fin Tube):-

Manufacturing Process: – Grooving and Embedding the Fin Stock in the Base Tubes.

Fin To Tube Bond:- Very Good

Heat Transfer Efficiency:- Excellent

Mechanical Resistance: – Very Good

Corrosion Protection: – Moderate

Temperature Range:- Up to Maximum 415 Deg C

Manufacturing Range (G Fin Tube/Grooved Fin Tube):-

|

Sr. No |

Particulars |

Range |

|

1 |

Base Tube Material |

Stainless Steel, Carbon Steel, Alloy Steel, Titanium, Copper, Duplex Stainless Steel, Inconel etc. (all material in the theoretical limit) |

|

2 |

Base Tube Outside Diameter |

12.70 mm to 38.10 mm |

|

3 |

Base Tube Thickness |

2.11 mm And Above |

|

4 |

Base Tube Length |

500 mm Min To 15000 mm |

|

5 |

Fin Material |

Aluminum, Copper, Stainless Steel, etc. |

|

6 |

Fin Thickness |

0.3mm ,0.35mm, 0.4mm, 0.45mm, 0.55mm, 0.60mm,0.65mm |

|

7 |

Fin Density |

236 FPM (6 FPI ) to 433 FPM ( 11 FPI ) |

|

8 |

Fin Height |

9.8 mm to 16.00 mm |

|

9 |

Bare Ends |

As per Client Requirement |

|

10 |

Manufacturing Capacity |

5,00,000 Meter Per Annum |

We can supply material on urgent delivery basis because of large stock and relations with raw material suppliers. We use only Prime Quality base tube and Aluminum Material.

The Extruded fin Tubes can be supplied with EN 10204 EN 3.1 and EN 3.2 certifications. We can provide Third Party Inspection from any reputed inspection agency.

1) What are Fin Tubes or Finned Tubes?

Fin Tubes, also known as Finned Tubes, are a type of heat exchanger tube. Finned Tubes are used mainly in an air-cooled type heat exchanger where the exchange of heat takes place between gas flowing on the fins and the fluid flowing inside the fin tubes. The main purpose of fin tubes is to increase the surface area of a tube to facilitate more exchange of heat between the medium and the air.

2) What is ‘G’ Fin Tube or Embedded Fin Tube?

As the name suggests, the embedded fin tube or G fin tube is an extended surface fin tube where the fins are externally applied on the base tubes. A groove is formed continuously on the base tube and the fin edge is inserted in the groove. After the fin is inserted in the groove a set of rollers is used to back fill the groove and the fin is then securely embedded in the base tube.

The strength of the Embedding or more commonly known as Fin to Tube bond test is checked by hanging a 3 Kg free wight to an Isolated fin. This ensures whether the fin has been Embedded into the base tube properly.

3) What is an extruded fin tube made of?

‘G’ Fin Tubes or Embedded Fin Tubes are made of two main components, Base Tube and Fin Strip material.

We can supply the ‘G’ Fin Tubes in the following combinations of Base Tube and Fin Material:

Base Tube Material: Carbon Steel, Alloy Steel, Mild Steel, Stainless steel and tubes manufactured by ERW or Seamless Process

Fin Material: Aluminum, Copper

4) Where are Extruded Fin Tubes or Bi-Metallic Fin Tubes used?

‘G’ Fin Tubes or Embedded Fin Tubes are mainly used in air fin coolers and many different types of air-cooled radiators. These types of ‘G’ Fin Tubes mainly find application in areas where the temperature for heat transfer is in a slightly higher range. The Embedded Fin Tubes are mainly used in places with higher temperature and where the working atmosphere is relatively less corrosive to the base tube.

Main industries in which the ‘G’ Fin Tubes find service are Process Chemical Plants, Refineries, Gas Processing Plants, Steel Plants, Power Plants, Fertilizer Manufacturing Plants, etc.

5) Why should you buy ‘G’ Fin Tubes manufactured by Anand Seamless?

Anand Seamless Tubes is the only tube or fin tube manufacturer in India where the Base Tubes and Fin Tubes are both manufactured under the same roof. Also, we are the only manufacturers in India to have certifications for Manufacturing of Carbon Steel and Alloy Steel Seamless Tubes and ‘G’ Fin Tubes or Embedded Fin Tubes at the same facility.

We are EIL (Engineers India Limited) approved manufacturer for manufacturing of Carbon Steel and Alloy Steel Seamless tubes and various types of finned tubes in the same manufacturing facility.

We are also IBR approved for the manufacturing of Carbon Steel and Alloy Steel Seamless tubes and this gives a strategic and commercial advantage to our clients as we have a big stock of base tube readily available.

There are many advantages like no hassles and additional costs to manage suppliers for Base Tube and Fin Tubes, no capital blocking for even a short period, saved transportation cost, TPI costs, and when you buy the Extruded or Bimetallic fin tubes from Anand Seamless Ltd.

We are strategically located in Chhatral India and hence for the requirements of ‘G’ Fin Tubes, Embedded Fin Tubes with SS/DSS base tube and Fin.