Alloy Steel Heat Exchanger Tubes – Straight

Our Product

Heat Exchanger Tubes – Straight

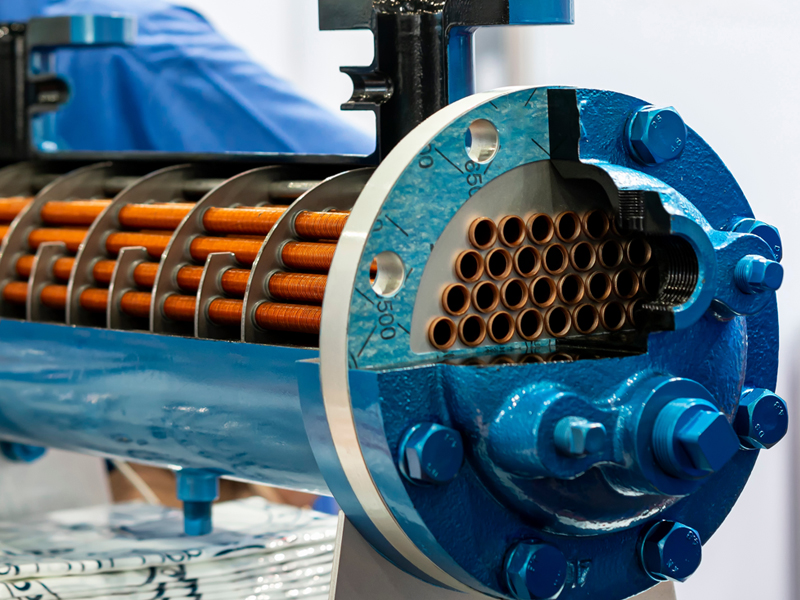

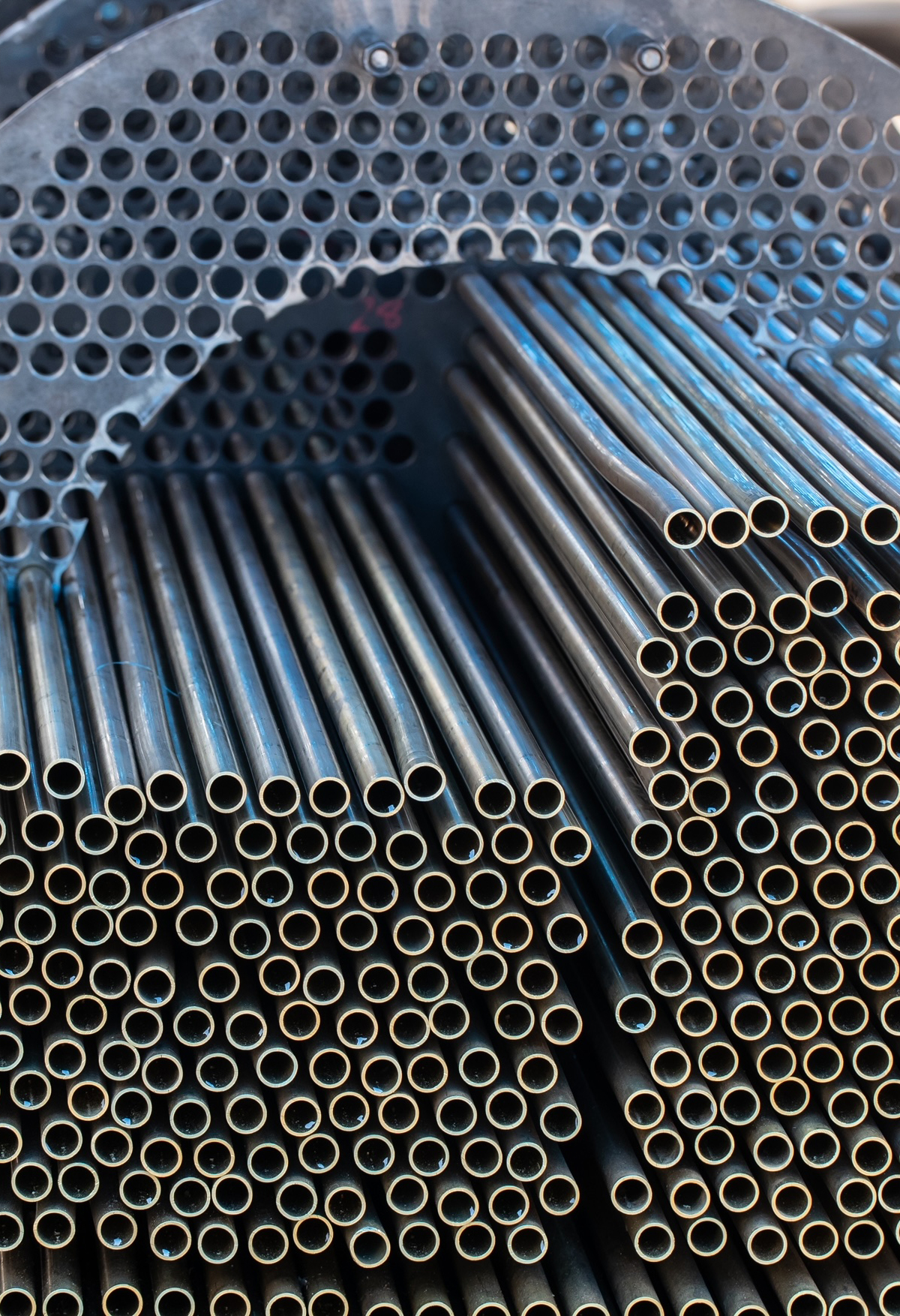

Anand Seamless Ltd. offers Cold Drawn Seamless Heat Exchanger Tubes (Straight) made from premium quality Alloy Steel, engineered specifically for high-performance heat transfer applications. These tubes are manufactured using the Drawn on Mandrel cold drawing process, which ensures precise dimensional tolerance, smooth internal and external surfaces, and enhanced mechanical properties.

Each tube undergoes heat treatment processes such as normalizing, annealing, stress relieving, or tempering as per the customer’s material and application requirements. The tubes are also multi-roll straightened to achieve straightness accuracy of up to 1 mm per 1000 mm.

Anand Seamless ensures quick delivery through large stock availability and offers stringent quality assurance, including 3.1 or 3.2 EN 10204 certificates and third-party inspection from agencies like TUV, DNV, Lloyd’s, SGS, etc.

Technical Specifications

|

Sr. No. |

Particulars |

Range |

|---|---|---|

| 1 | Type | Straight Tube |

| 2 | Material of Construction (MOC) | Alloy Steel |

| 3 | Tube Outside Diameter | 6.00 mm to 219.00 mm |

| 4 | Tube Wall Thickness | 0.85 mm to 21.00 mm |

| 5 | Tube Length | 1.0 Meter to 27.0 Meter |

| 6 | Straightness Accuracy | Up to 1 mm per 1000 mm |

| 7 | Manufacturing Process | Cold Drawn (Drawn on Mandrel) |

| 8 | Heat Treatment | Normalized/Annealed/Stress Relieved/Tempered |

| 9 | Inspection & Certification | EN 10204 3.1 / 3.2, TPI available |

International Standards

- ASTM A209 / A213

- ASME SA213

- EN 10216-2 / DIN 17175

- BS 3059

- JIS G3461 / G3462

- TEMA (for Heat Exchangers)

- Indian Boiler Regulation (IBR – Well Known Pipe & Tube Maker)

Applications

Industries Served

Our Straight Heat Exchanger Tubes are ideal for use in: