Alloy Steel Heat Exchanger Tubes – U Bend

Our Product

Heat Exchanger Tubes – U Bend

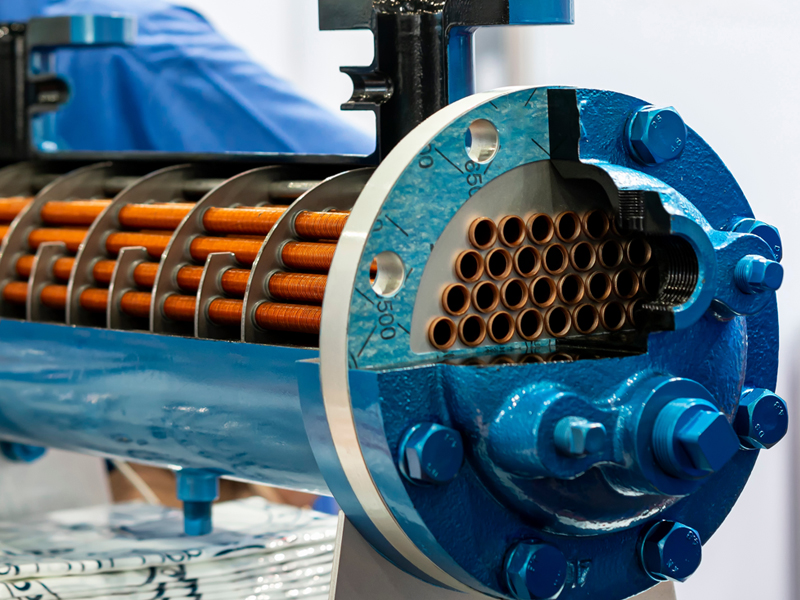

Anand Seamless Ltd. specializes in manufacturing U Bend Heat Exchanger Tubes made from high-grade Alloy Steel. These tubes are designed for compact heat exchanger designs where space optimization and efficient thermal transfer are key. The U-bend configuration is ideal for high-pressure and high-temperature applications where straight tubes are impractical.

Our in-house U-bending facility is fully equipped to produce tubes with tight radius bends and minimal wall thinning. Stress relieving is carried out on all bends in compliance with TEMA (Tubular Exchanger Manufacturers Association) standards, ensuring long-term performance and reliability.

Technical Specifications

|

Sr. No. |

Particulars |

Range |

|---|---|---|

| 1 | Type | U Bend Tube |

| 2 | Material of Construction (MOC) | Alloy Steel |

| 3 | Tube Outside Diameter | 6.00 mm to 101.00 mm |

| 4 | Tube Wall Thickness | 0.85 mm to 12.70 mm |

| 5 | Bending Radius (R) | Min 1.5 D to Max 1000 mm |

| 6 | Tube Length (Legs) | 1.0 Meter to 27.0 Meter |

| 7 | Heat Treatment | Stress Relieved (as per TEMA) |

| 8 | Manufacturing Process | Cold Drawn + Precision Bending |

| 9 | Inspection & Certification | EN 10204 3.1 / 3.2, TPI available |

Applicable Standards

- ASTM A209 / A213

- ASME SA213

- DIN 17175 / EN 10216-2

- JIS G3461 / G3462

- BS 3059

- TEMA – For stress relief and U-bend quality

- Indian Boiler Regulation (IBR)

Applications

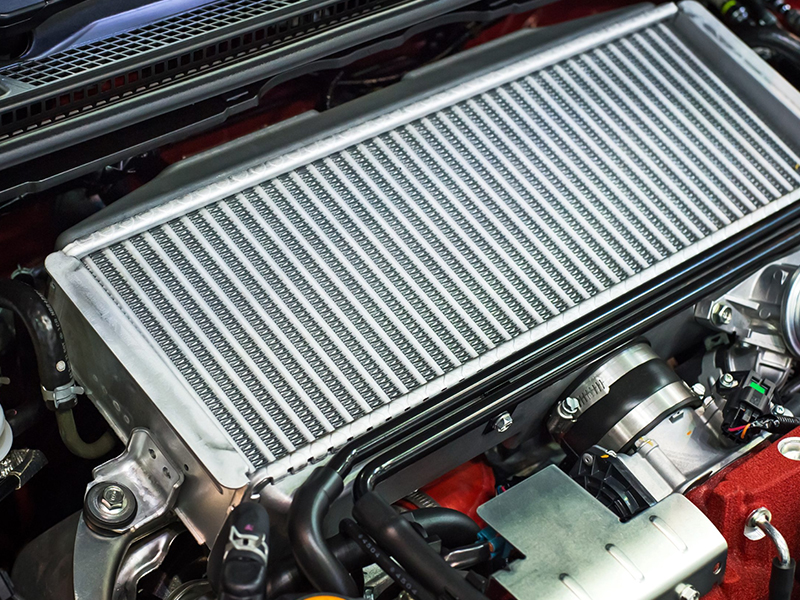

U-bent tubes are extensively used in

We also ensure complete traceability and supply with EN 10204 3.1 / 3.2 certification and third-party inspection as required by clients.