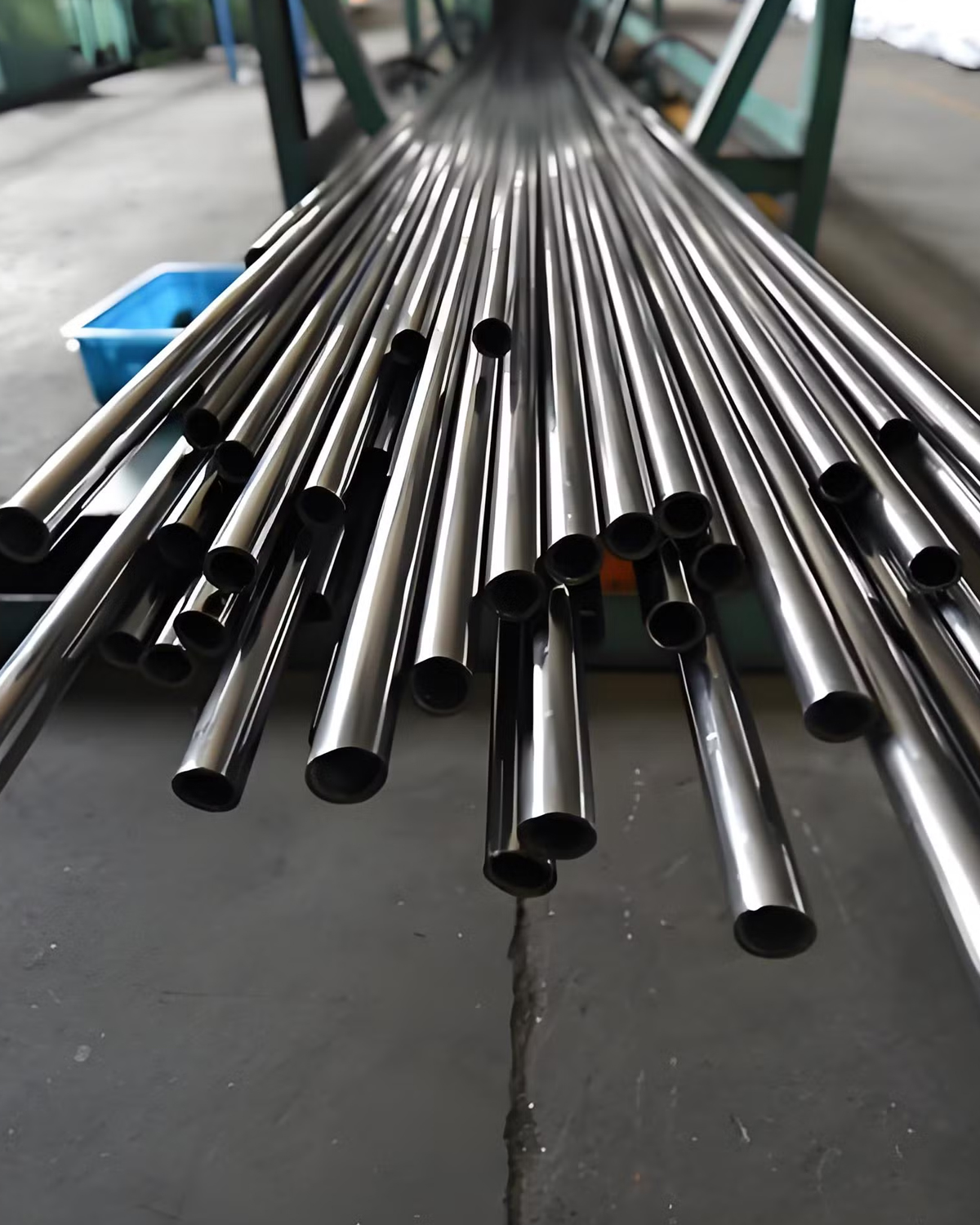

Stainless Steel Mechanical Tubes

Our Product

Mechanical Tubes

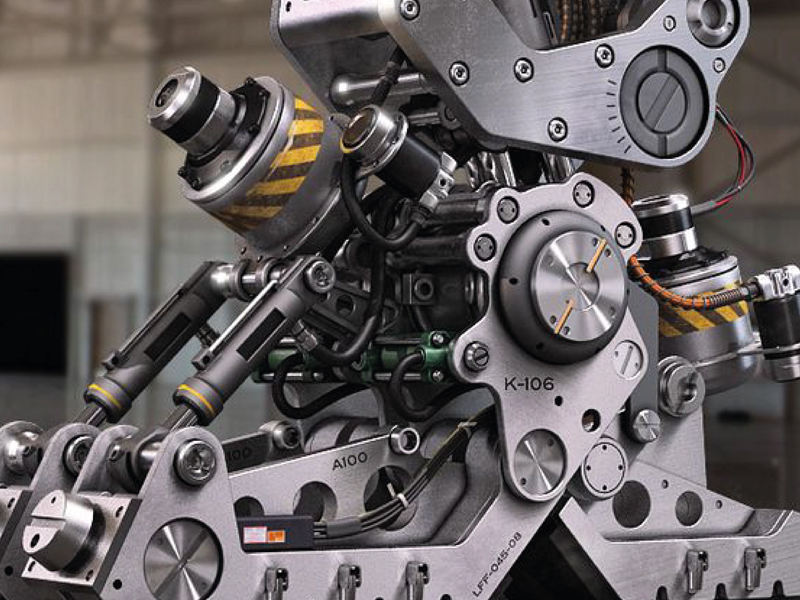

/ Automobile Application Tubes

Anand Seamless Ltd. offers precision-engineered Mechanical Tubes suitable for a variety of automotive, hydraulic, and general engineering applications. Manufactured using the Cold Drawn Mandrel Process, these tubes provide tight dimensional tolerances, excellent surface finish, and high tensile strength, making them ideal for critical use cases.

We use Tungsten Carbide Dies and Mandrels to ensure high accuracy in both inner and outer diameters. Our advanced straightening technology delivers straightness of up to 1mm per 1000 mm, which is crucial for direct use in honing or machining operations.

These tubes are available with EN 10204 3.1 / 3.2 certification, and can be inspected by third-party agencies like TUV, DNV, or SGS as per client requirement.

Technical Specifications

|

Sr. No. |

Particulars |

Range |

|---|---|---|

| 1 | Type | Mechanical Tubes – Straight Length |

| 2 | Material of Construction (MOC) | Stainless Steel |

| 3 | Tube Outside Diameter | 6.00 mm to 101.00 mm |

| 4 | Tube Wall Thickness | 0.85 mm to 12.70 mm |

| 5 | Tube Length | Fixed or Random Length up to 15.0 Meters |

| 6 | Manufacturing Process | Cold Drawn on Mandrel |

| 7 | Heat Treatment | Normalized, Annealed, Stress Relieved, Tempered |

| 8 | Certification | EN 10204 3.1 / 3.2, TPI available |

International Standards Applicable

- EN 10305-1: E215 / E235 / E355

- DIN 2391 – ST35 / ST45 / ST52

- ASTM A513 (as applicable)

- IBR for pressure tube applications (if applicable)

- 304, 316, 321, 410

Frequently Asked Questions (FAQs)

Are these tubes ready for honing operations?

What industries typically use mechanical tubes?

Automotive, textile machinery, hydraulics, and defence industries.

Are fixed-length orders possible?

Absolutely. We offer both fixed and random lengths as per client requirements.

What makes your mechanical tubes suitable for precision engineering?

The use of tungsten carbide tooling and mandrels, strict straightness control, and precision heat treatment processes.