Extruded Finned Tubes

Our Product

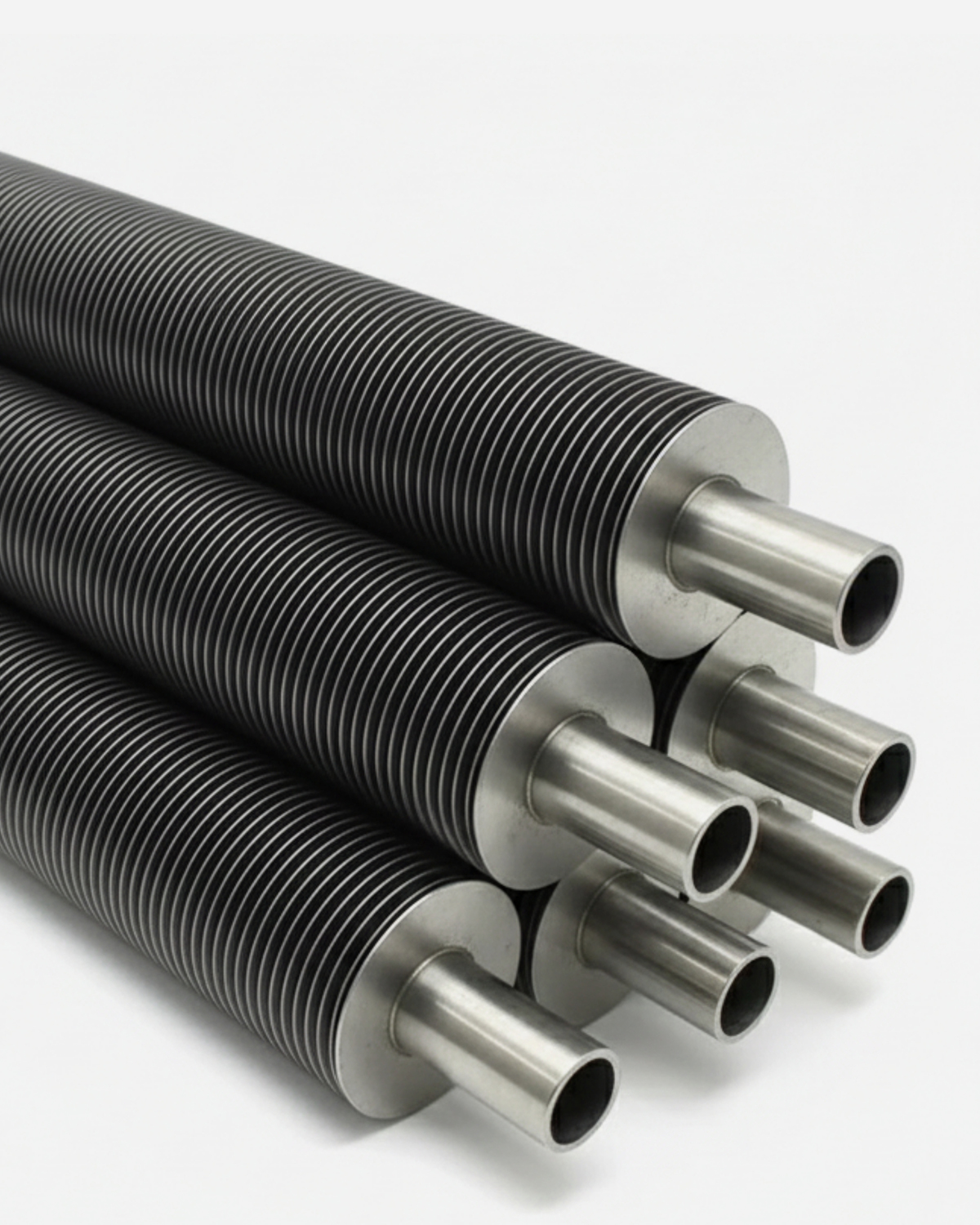

Extruded Finned Tubes

(Bi-Metallic Fin Tubes)

Anand Seamless Ltd. manufactures Extruded Finned Tubes, also known as Bi-Metallic Fin Tubes, using advanced cold extrusion technology. In this process, aluminum or copper fins are integrally extruded over a base tube (carbon steel, alloy steel, stainless steel, etc.) with high mechanical bonding and optimal heat transfer properties.

These tubes offer superior resistance to corrosion, high mechanical strength, and longer operational life due to the complete encapsulation of the base tube. They can also be frequently cleaned using high-pressure jets, which reduces downtime and enhances the life of the cooling systems.

Available in solid or serrated fin profiles, we offer full customization of fin density, height, thickness, and bare ends.

Technical Specifications

|

Sr. No. |

Particulars |

Range |

|---|---|---|

| 1 | Base Tube Material | Carbon Steel, Alloy Steel, Stainless Steel, Titanium, Copper, Inconel, Duplex |

| 2 | Base Tube OD | 12.70 mm to 38.10 mm |

| 3 | Base Tube Thickness | 1.50 mm and above |

| 4 | Base Tube Length | 500 mm to 21,000 mm |

| 5 | Fin Material | Aluminium, Copper |

| 6 | Fin Thickness | 0.3 to 0.65 mm |

| 7 | Fin Height | 9.8 mm to 16.00 mm |

| 8 | Fin Density | 197 FPM (5 FPI) to 433 FPM (11 FPI) |

| 9 | Bare Ends | As per client requirements |

| 10 | Manufacturing Capacity | 5,00,000 Metres Per Annum |

| 11 | Temperature Range | Up to 300°C |

| 12 | Bond Type | Excellent – via Cold Extrusion |

International Standards Applicable

- ASTM B359 / B891 (For Fin Tubes)

- EN 10204 – 3.1 / 3.2 certification

- Additional standards as per base tube (ASTM, ASME, DIN, etc.)

Frequently Asked Questions (FAQs)

Why choose extruded fin tubes over other types?

Extruded fins offer excellent bonding, corrosion protection, and can withstand high-pressure cleaning—ideal for long-term industrial use.

Can these be used in food-grade applications?

Yes. With stainless steel or copper base tubes and aluminium fins, they are suitable for food and agricultural heat exchange systems.

Are serrated fins available?

Yes, we offer both solid and serrated fin types depending on the application.

What’s the maximum working temperature?

Up to 300°C, making them ideal for high-temperature gas cooling systems.