Crimped Fin Tube

Our Product

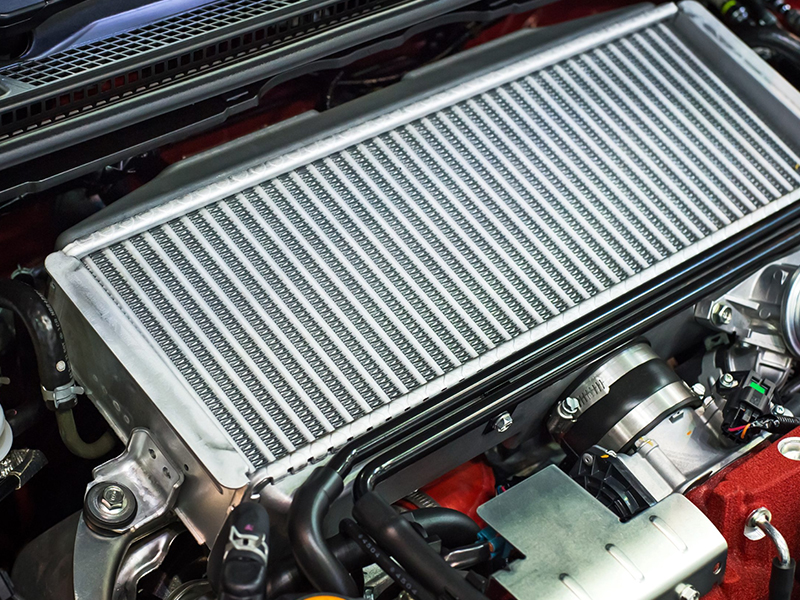

Crimped Fin Tube

Crimped Finned Tubes are produced by helically tension winding the fin material onto the base tube. The fin strip base is pre-formed through precision rollers to ensure uniform fin spacing and a secure mechanical bond.

Sizing

| OD: | 15.88 mm to 219.00 mm OD (⅜” NB pipe to 8” NB pm) |

| THK: | 0.15mm, 2.00mm |

| Length: | 500 mm Min to 15000 mm |

Base Tube Material

- Stainless Steel

- Carbon Steel

- Alloy Steel, Titanium

- Copper, Duplex Stainless Steel

- Inconel etc.

Fin Material/ Fin Thickness

- Aluminum

- Copper, Stainless Steel

- Carbon Steel

Applications

Industries Served

·

Find your answer

·

Find your answer

·

Find your answer

·

Find your answer

·

Find your answer

·

Find your answer

·

Find your answer

·

Find your answer

·

Find your answer

·

Find your answer

Frequently Asked Questions (FAQs)

What is the key advantage of studded finned tubes?

They provide maximum durability and heat transfer efficiency in high-temperature, fouling-prone applications.

Are custom stud pitches possible?

Yes. We manufacture stud pitches based on thermal design or client drawings.

Can studded tubes be used for air preheaters?

Yes. We offer wrapping on carbon steel, alloy steel, stainless steel, copper, and other alloys.

Do you offer inspection and testing?

Yes. Visual inspection, dye penetrant testing, and ultrasonic testing are available per client request.