L / LL / KLM Type Finned Tubes

Our Product

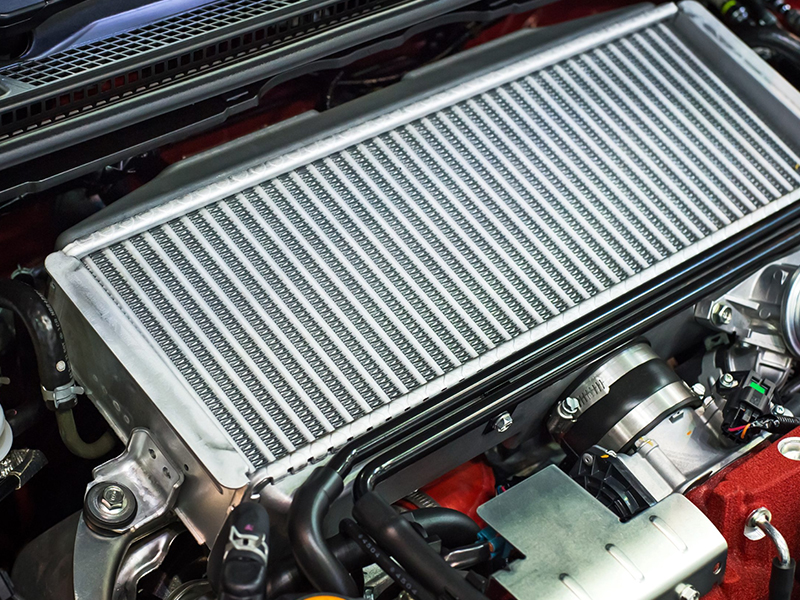

L / LL / KLM Type Finned Tubes

(Wrap Around Fin Tubes)

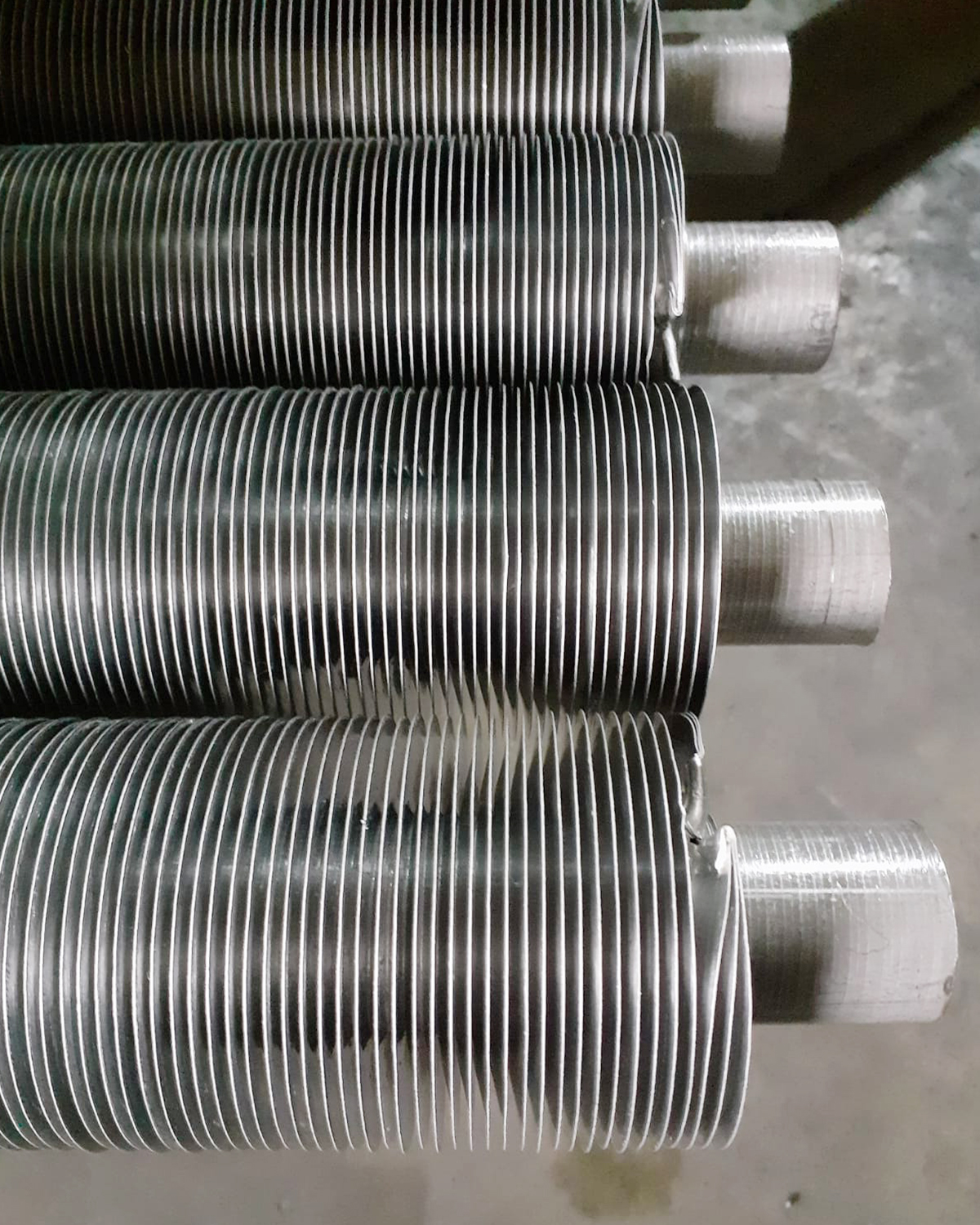

- L-Type Fin Tubes: Feature an ‘L’-shaped foot that wraps around the base tube, offering basic mechanical grip and moderate corrosion protection.

- LL-Type Fin Tubes: An upgraded version where each successive fin covers the foot of the previous one—ensuring enhanced corrosion resistance.

- KLM-Type Fin Tubes (Knurled): The most robust wrap-around type with knurled tube and fin base, allowing better bonding and improved thermal performance.

Technical Specifications

|

Sr. No. |

Particulars |

Range |

|---|---|---|

1 |

Base Tube Material |

Carbon Steel, Alloy Steel, Stainless Steel, Titanium, Copper, Inconel, Duplex |

2 |

Base Tube OD |

12.70 mm to 38.10 mm |

3 |

Base Tube Thickness |

1.25 mm and above |

4 |

Base Tube Length |

500 mm to 21,000 mm |

5 |

Fin Material |

Aluminium, Copper, Stainless Steel |

6 |

Fin Thickness |

0.3 to 0.65 mm |

7 |

Fin Height |

9.8 mm to 16.00 mm |

8 |

Fin Density |

236 FPM (6 FPI) to 433 FPM (11 FPI) |

9 |

Temperature Range |

Up to 175°C |

10 |

Fin-to-Tube Bond |

Mechanical (via spiral tension) |

11 |

Manufacturing Capacity |

5,00,000 Metres Per Annum |

12 |

Bare Ends |

As per client requirement |

International Standards Applicable

- EN 10204 – 3.1 / 3.2 certification

- Fin tubes manufactured to ASTM and DIN tolerances (on request)

- Suitable for TEMA specifications where applicable

Applications

Frequently Asked Questions (FAQs)

What is the main advantage of L/LL/KLM-type fin tubes?

They are cost-effective, easily customizable, and suitable for applications with moderate heat transfer and low-to-mid temperatures.

How do KLM fin tubes differ from L-type?

KLM tubes include knurling, which improves bonding between the fin and tube and enhances heat transfer efficiency.

Can wrap-around fins be applied to any tube material?

Yes. We offer wrapping on carbon steel, alloy steel, stainless steel, copper, and other alloys.

What are typical industries using these tubes?

Used in dryers, food processing, agriculture equipment, air coolers, and HVAC systems.