High Frequency Welded Spiral Fin Tubes Solid

Our Product

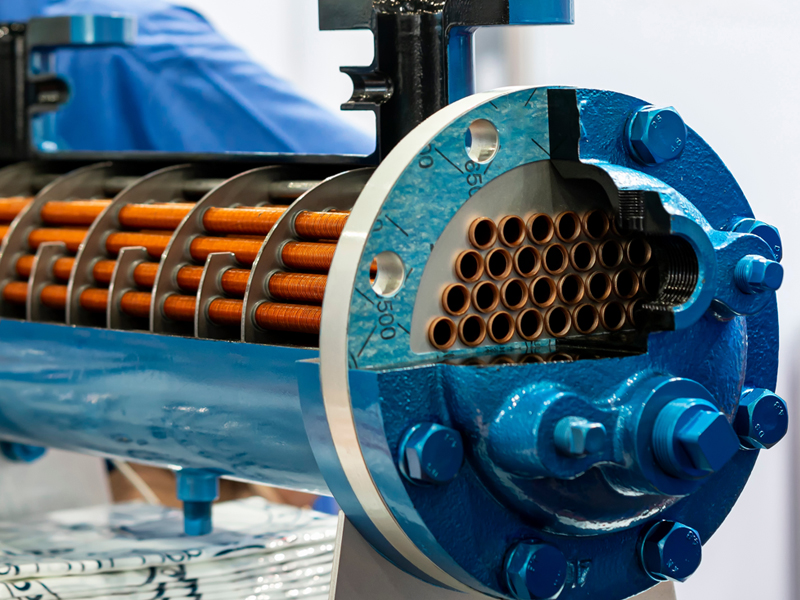

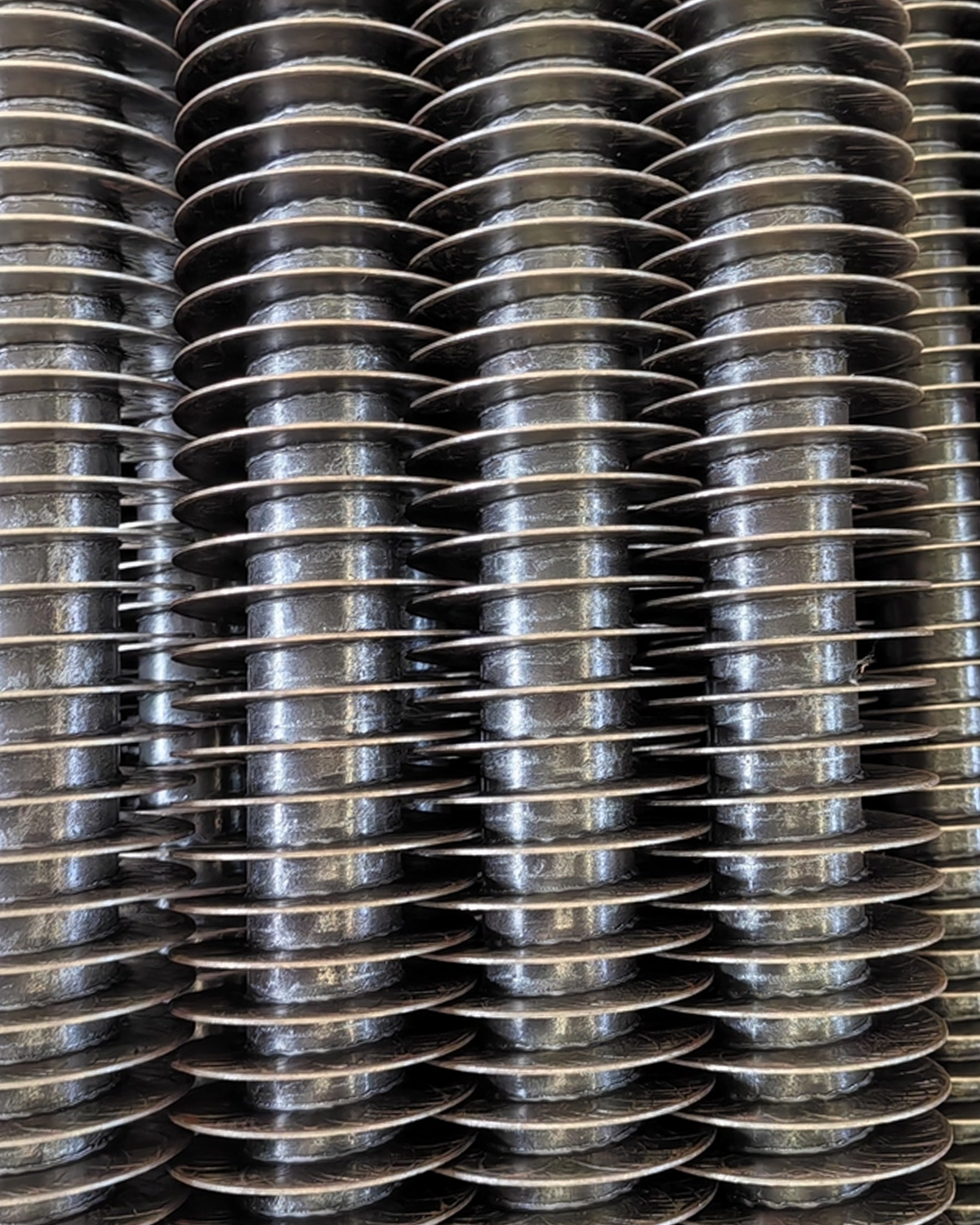

Welded Spiral Fin Tubes

(Solid Type)

- Strong metallurgical bonding

- Excellent heat transfer performance

- High resistance to vibration and mechanical stresses

Technical Specifications

|

Sr. No. |

Particulars |

Range |

|---|---|---|

1 |

Base Tube Material |

Carbon Steel, Alloy Steel, Stainless Steel |

2 |

Base Tube OD |

31.75 mm to 225 mm |

3 |

Base Tube Thickness |

As per design requirement |

4 |

Tube Length |

Up to 18,000 mm |

5 |

Fin Material |

Carbon Steel, Stainless Steel |

6 |

Fin Height |

9.8 mm to 25 mm |

7 |

Fin Thickness |

0.8 mm to 1.5 mm |

8 |

Fin Pitch (Density) |

79 FPM (2 FPI) to 276 FPM (7 FPI) |

9 |

Fin Type |

Solid Spiral Fin |

10 |

Bonding Method |

High-Frequency Welded (100% Metallurgical) |

11 |

Temperature Range |

Up to 400°C |

12 |

Cleaning Method |

Suitable for mechanical or chemical cleaning |

International Standards Applicable

- ASTM A213 / A335 (Base Tube)

- EN 10204 – 3.1 / 3.2 Certification

- API 560 and related petrochemical thermal codes

- Client-specific drawings/specs for thermal performance

Frequently Asked Questions (FAQs)

What’s the key benefit of spiral welded fin tubes?

Spiral welded fin tubes have excellent thermal efficiency, high mechanical strength, and are ideal for dusty/flue gas environments.

Are these fins suitable for high-temperature applications?

Yes. They are generally used in applications up to 400°C, and material selection can push this higher.

Can you supply custom fin pitch or height?

Absolutely. We manufacture as per your thermal design or project specification.

Are serrated versions also available?

Yes. For enhanced turbulence and heat transfer, serrated spiral fin tubes are available.