Studded Finned Tubes

Our Product

Studded Finned Tubes

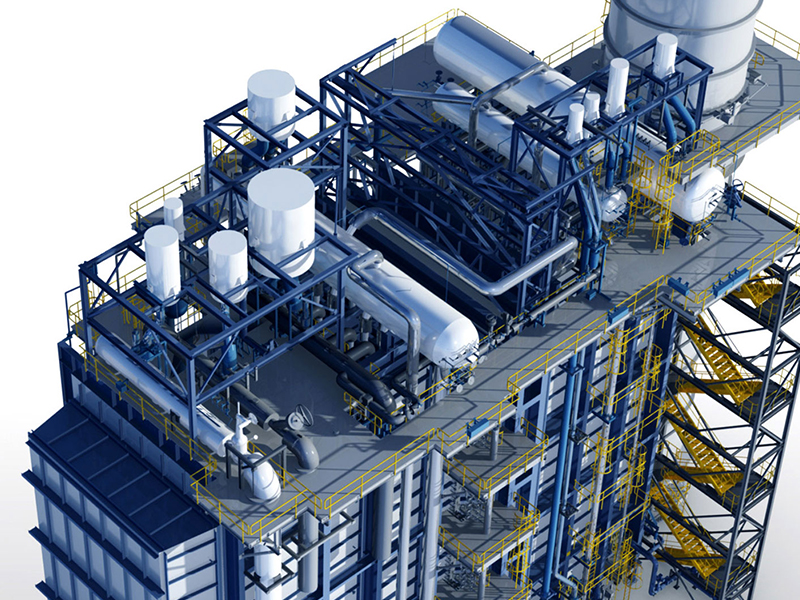

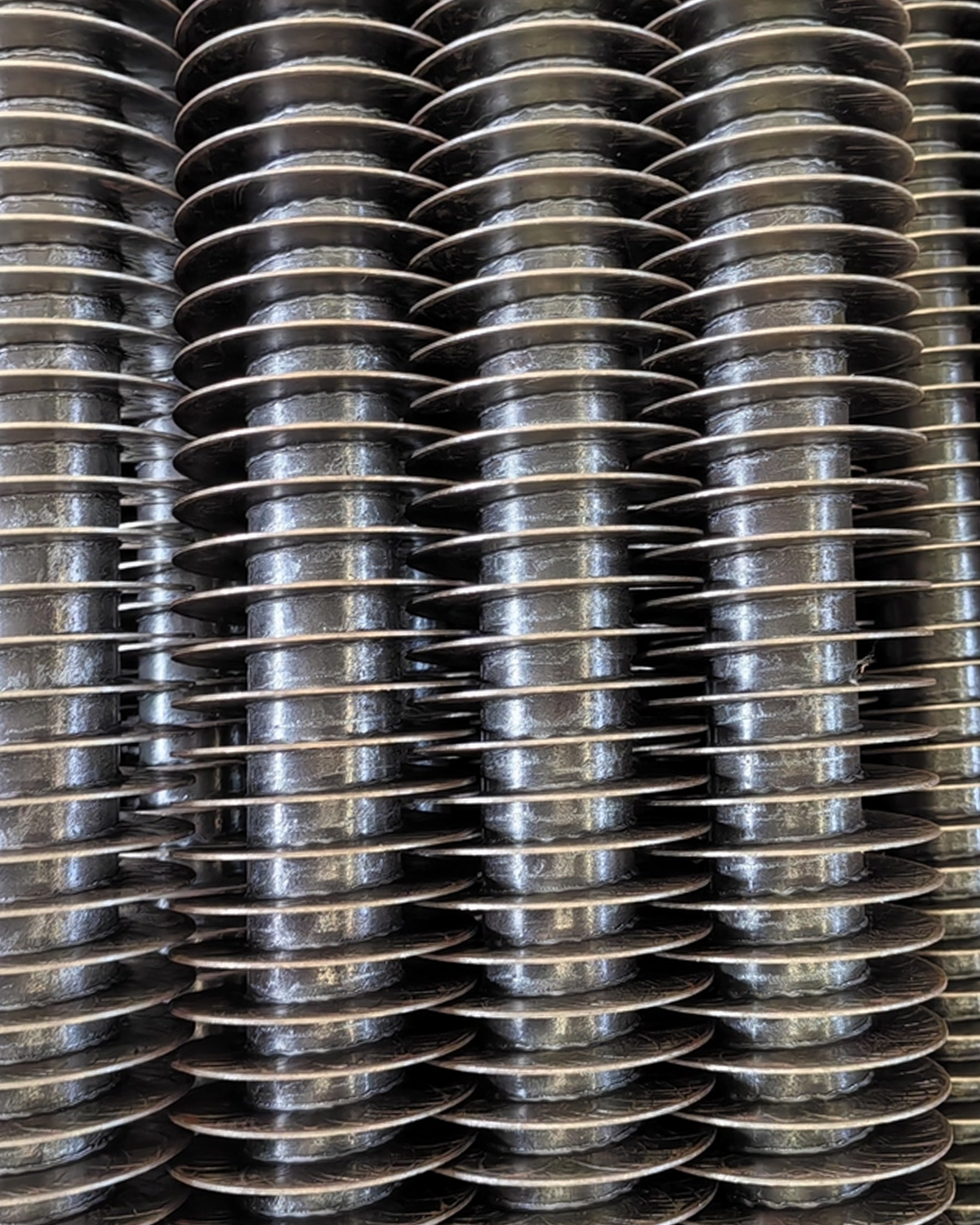

Anand Seamless Ltd. manufactures Studded Finned Tubes using precision electric resistance welding (ERW) technology to fuse metal studs directly onto the outer surface of seamless tubes. This high-strength bonding method ensures that each stud is welded with full fusion for maximum thermal efficiency and structural integrity.

Studded fin tubes are ideal for applications involving:

- High-temperature flue gases

- Aggressive corrosion or fouling

- High-pressure environments

By increasing the external surface area, studded tubes improve heat transfer while minimizing the risk of corrosion under the fins. Their rugged construction allows for long service life and easy cleaning under demanding process conditions.

Technical Specifications

|

Sr. No. |

Particulars |

Range |

|---|---|---|

1 |

Base Tube Material |

Carbon Steel, Alloy Steel, Stainless Steel |

2 |

Tube Outside Diameter (OD) |

60 mm to 200 mm |

3 |

Stud Type |

Cylindrical or Rectangular |

4 |

Stud Diameter |

As per design requirements |

5 |

Stud Height |

12.7 mm to 63.5 mm |

6 |

Stud Pitch |

Standard or Custom (as per heat transfer need) |

7 |

Manufacturing Process |

Electric Resistance Welding (ERW) |

8 |

Heat Treatment (if applicable) |

Normalizing or Stress Relieving |

9 |

Fin-to-Tube Bond |

Fully Fused Metallurgical Bond |

10 |

Manufacturing Capacity |

87,60,000 Studs per Year |

11 |

Inspection |

100% Visual + Penetrant / UT (on request) |

International Standards Applicable

- API 560 (for fired heaters)

- EN 10204 – 3.1 / 3.2 certifications

- Custom specifications based on engineering drawings

- ASTM / ASME / DIN base tube material compliance

Frequently Asked Questions (FAQs)

What is the key advantage of studded finned tubes?

They provide maximum durability and heat transfer efficiency in high-temperature, fouling-prone applications.

Are custom stud pitches possible?

Yes. We manufacture stud pitches based on thermal design or client drawings.

Can studded tubes be used for air preheaters?

Yes. We offer wrapping on carbon steel, alloy steel, stainless steel, copper, and other alloys.

Do you offer inspection and testing?

Yes. Visual inspection, dye penetrant testing, and ultrasonic testing are available per client request.