Quick Inquiry

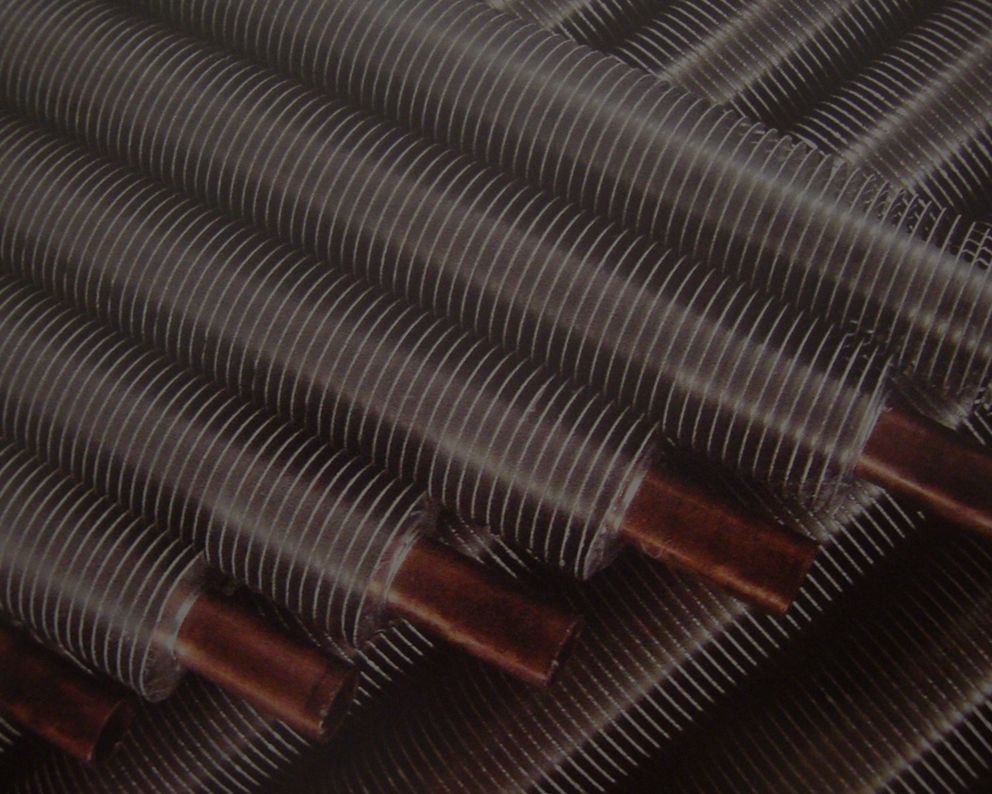

Heat exchanger tubes find application in heat transfer. They are an essential component in steel plants, power plants, refineries, fertilizer plants, chemical factories and shipbuilding.

A poorly installed heat exchanger tube or one that does not match up to specifications can lead to failure of the entire heat exchanger systems. So whether you are purchasing a heat exchanger tube or replacing an old unit, here are top five mistakes that you should avoid making:

Excessive Fouling

Excessive fouling in a heat exchanger tube can be a result of inadequate cleaning of the system or due to chemical fouling and corrosion of the material. In either case, the end-result is damaging. It can reduce the efficiency of your heat exchanger and increase energy consumption.

For instance, food products that contain high levels of protein can cause excessive fouling in the heat exchanger. Where waste management systems are concerned, the threat is from limescale.

The best way to avoid excessive fouling is by picking out the right type of heat exchanger. You can pick scraped surfaces or corrugated tubes. These reduce fouling in the system by increasing turbulence. You can also ensure the maintenance of the right temperature to keep your heat exchanger safe.

Wrong Material Choice

Carbon steel is a more affordable option as compared to stainless steel. But remember that cheaper isn’t necessarily a better option. Stainless steel is better at withstanding corrosion and chemical reaction. Specifying the right material for your heat exchanger is critical. Picking out the wrong material can cause catastrophic damage to your unit.

Incorrect Pressure Drop

Incorrect pressure drop in the heat exchanger tube can lead to contamination and even failure of the heat exchanger. The reason for this is usually a pressure drop that is higher than the specifications provided for the design. It can also be due to a change in the raw material specification.

To avoid this mistake, make sure you ask for full details of the product from your suppliers. Also, do test the product before purchasing it.

Poor Location

Ensure that your heat exchanger tube is the right size and has not been placed in a congested space. A common problem is that heat exchangers are placed in a space that is crammed with wires or complex pipework. Look for a heat exchanger that can fit into the space that you have. This helps in cleaning and maintenance of the exchanger.

Insufficient Capacity

A lot of people pick out smaller units to save money. However, this can be damaging to your business in the long run. The best way to address this issue is by picking out a modular design, which allows you to scale up production as and when required. It may incur you some cost to arrange for the additional space, but it is better than purchasing an over-specified unit.

Need expert advice regarding heat exchanger tubes? Reach out to the experts at Anand Seamless Ltd – leading heat exchanger manufacturer in India.

Reach Out for All Your Heat Exchanger Requirements

Anand Seamless Ltd offers a wide range of products including finned tubes, fin tube heat exchangers, etc. From high-quality seamless tubes to hydraulic tubes and from seamless pipes to mechanical tubes, we have a huge range of products. To know more you can call us at +91-9099996851 or send your queries to inquiry@anandseamless.com.

Also Read:

lATEST BLOG |

|

How to Choose Right Grade Carbon Steel Seamless Tubes

Carbon steel seamless tubes are essential componen |

|

Basics of Aluminum Finned Tubes

In the world of heat exchange technology, aluminiu |

|

How to Enhance Mechanical Tubes for Various Applications

Mechanical tubes form the backbone of various indu |

|

Why Are U-Tube Heat Exchangers Undeniably Vital: A Complete Guide

In the landscape of industrial heat exchange syste |

|

Introductory Guide to Economizer Tubes

In the dynamic landscape of industrial operations, |