Quick Inquiry

Heat Exchanger Tubes are used in many industries that require the transportation of important fluids in their appropriate temperature. Many industries are looking for more efficiency generating results. For such industries, there are plant designers who have come up with Counter-flow heat exchangers that allow the industries to generate higher output and income.

But before we delve into the counter flow heat exchanger, it is important to understand the types of heat exchangers that the most reputed heat exchanger manufacturers in India produce.

There are Three Types of Heat Exchanger Tubes:

- 1. Plate Heat Exchanger

- 2. Shell and Heat Exchanger Tubes

- 3. Air Cooled Heat Exchanger

1. Shell and Heat Exchanger Tubes

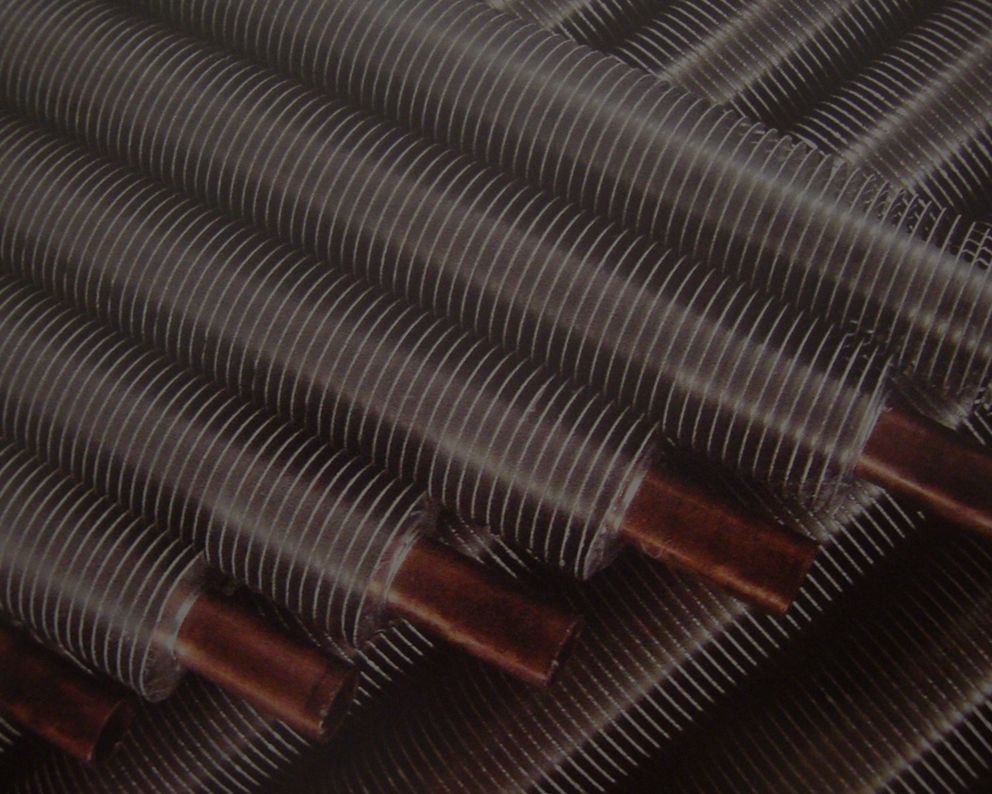

Shell and Heat Exchanger Tubes are a large number of small tubes, arranged inside a cylindrical shell. The tubes are arranged using a ‘tube stack’ or tube bundle which either be floating or fixed. The floating tube stack allows the tubes to contract and expand and also allows the tubes to be easily serviced and maintained.

2. Plate Heat Exchanger

Plate Heat Exchangers are similar to the shell and heat exchanger tubes with only one difference. Instead of tubes, Plate Heat Exchanger uses plates and is usually gasketed or brazed depending upon its use and flow of fluids. These are generally used in food and beverages industry.

3. Air Cooled Heat Exchanger

These are generally used in vehicles where there is no permanent solution to cool the engine down or under the absence of a source of water. There are several combinations inside the Air Cooled Heat Exchanger.

Now, Counterflow is generally observed in shell and heat exchanger tubes and thus if you have an industry that uses them, the following is worth your read.

What is Counter Flow?

Counter Flow refers to the opposite flow of cool and hot liquids in the through the tubes in the shell, such that the liquids flow against each other. To understand more, you need to know more about Parallel Flow and Counter Flow.

1. Counter Flow Heat Exchanger

While having a counterflow setup, the fluids inside the shell and heat exchanger tubes travel in different or opposite directions. The counterflow allows:

The counterflow allows:

- The heat to distribute evenly through the heat exchanger

- The cold fluid maintains its temperature

2. Parallel Flow Heat Exchanger

In the parallel flow heat exchanger, both the hot and cold fluid travel in the same direction inside the shell. It will help to cool the hot fluid down but not as efficiently as Counter Flow Heat Exchanger.

Advantages Of Counter Flow Heat Exchanger

Business is all about numbers so we would like to let you know the number in numerical.

- If you have a larger shell: Counter Flow will be able to increase the efficiency by 10 to 11 per cent

- If you have a smaller shell: Counter Flow will be able to increase its efficiency by 1 to 2 per cent

Thus industries with big plants can benefit greatly from introducing a counterflow into their heat exchanger shell and tubes.

Explore The Best Heat Exchanger Manufacturer’s Collection!

Our heat exchanger tubes are of a great application in Cryogenic and other Pressure Vessels, high-pressure equipment, Tube sheets of Heat Exchangers, Air Pre Heater, Boilers, Finned Tubes, Air Cooler Tubes, and more.

Our Heat Exchangers are Used in Several Industries Including:

- Refineries

- Power Plants

- Steel Plants

- Chemical Factories

- Fertilizer plants

- Ship Building, and many more!

We believe in client satisfaction and thus provide custom solutions. Call us on +91-9099996851 or drop us a mail on inquiry@anandseamless.com in case of any inquiry or if you wish to have an instant quote!

lATEST BLOG |

|

How to Choose Right Grade Carbon Steel Seamless Tubes

Carbon steel seamless tubes are essential componen |

|

Basics of Aluminum Finned Tubes

In the world of heat exchange technology, aluminiu |

|

How to Enhance Mechanical Tubes for Various Applications

Mechanical tubes form the backbone of various indu |

|

Why Are U-Tube Heat Exchangers Undeniably Vital: A Complete Guide

In the landscape of industrial heat exchange syste |

|

Introductory Guide to Economizer Tubes

In the dynamic landscape of industrial operations, |