G-Type Finned Tubes

Our Product

G-Type Finned Tubes

(Embedded Fin Tubes)

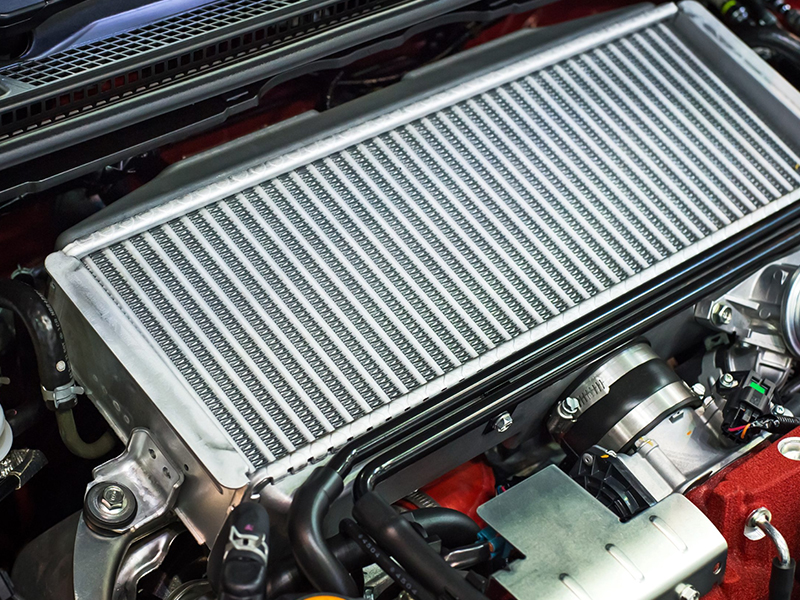

Anand Seamless Ltd. manufactures G-Type Finned Tubes, also referred to as Embedded Fin Tubes or Grooved Fin Tubes, designed for applications involving elevated temperatures and moderate corrosion environments. In this method, the fin strip is mechanically embedded into a pre-cut groove on the base tube and then backfilled to ensure strong bonding.

This manufacturing technique offers excellent heat transfer efficiency and strong mechanical adherence between the fin and base tube, making it.

The backfilling ensures long operational life and resistance to fin loosening. These finned tubes are manufactured in compliance with EN 10204 certifications and can be custom designed in terms of materials, fin height, density, and length.

Technical Specifications

|

Sr. No. |

Particulars |

Range |

|---|---|---|

| 1 | Base Tube Material | Carbon Steel, Alloy Steel, Stainless Steel, Titanium, Copper, Inconel, Duplex |

| 2 | Base Tube OD | 12.70 mm to 38.10 mm |

| 3 | Base Tube Thickness | 2.00 mm and above |

| 4 | Base Tube Length | 500 mm to 21,000 mm |

| 5 | Fin Material | Aluminium, Copper, Stainless Steel |

| 6 | Fin Thickness | 0.3 to 0.65 mm |

| 7 | Fin Height | 9.8 mm to 16.00 mm |

| 8 | Fin Density | 236 FPM (6 FPI) to 433 FPM (11 FPI) |

| 9 | Temperature Range | Up to 415°C |

| 10 | Fin-to-Tube Bond | Very Good (via Mechanical Embedding) |

| 11 | Manufacturing Capacity | 5,00,000 Metres Per Annum |

| 12 | Bare Ends | As per client requirement |

International Standards Applicable

- EN 10204 – 3.1 / 3.2

- Custom inspection standards as per client need

- Base tube compliance: ASTM / ASME / DIN / JIS standards

Applications

Frequently Asked Questions (FAQs)

What does "G" stand for in G-Type Fin Tubes?

“G” refers to Grooved, indicating that the fin is embedded into a machined groove on the tube surface.

What’s the difference between G-type and L-type finned tubes?

Are these suitable for corrosive atmospheres?

G-Type fin tubes are suitable for moderate corrosion environments. For aggressive corrosion, extruded or LL/KLM types are preferable.

Can G-Type fin tubes be cleaned with pressure jets?

Moderate mechanical resistance allows for cleaning, but care must be taken compared to extruded types.