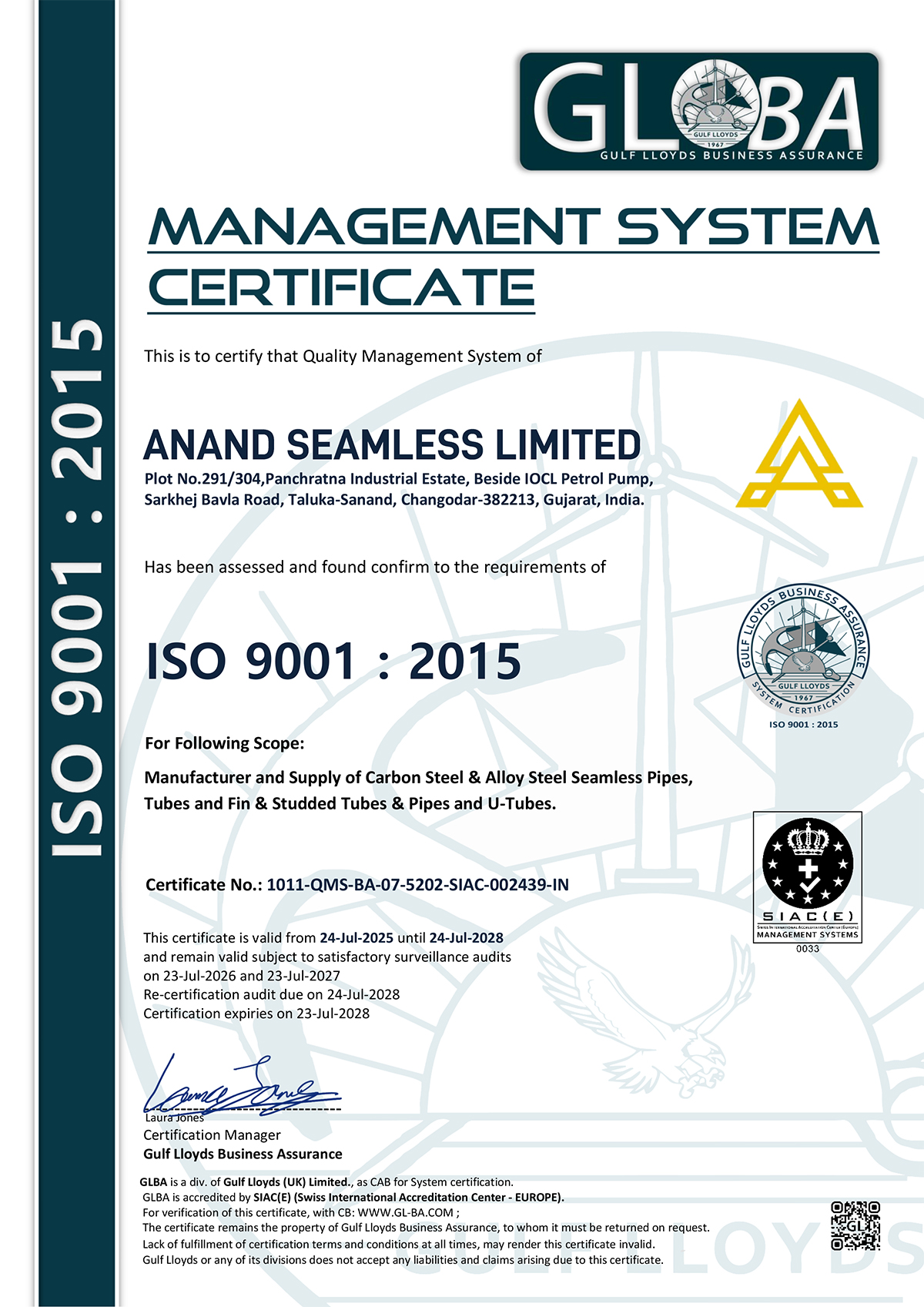

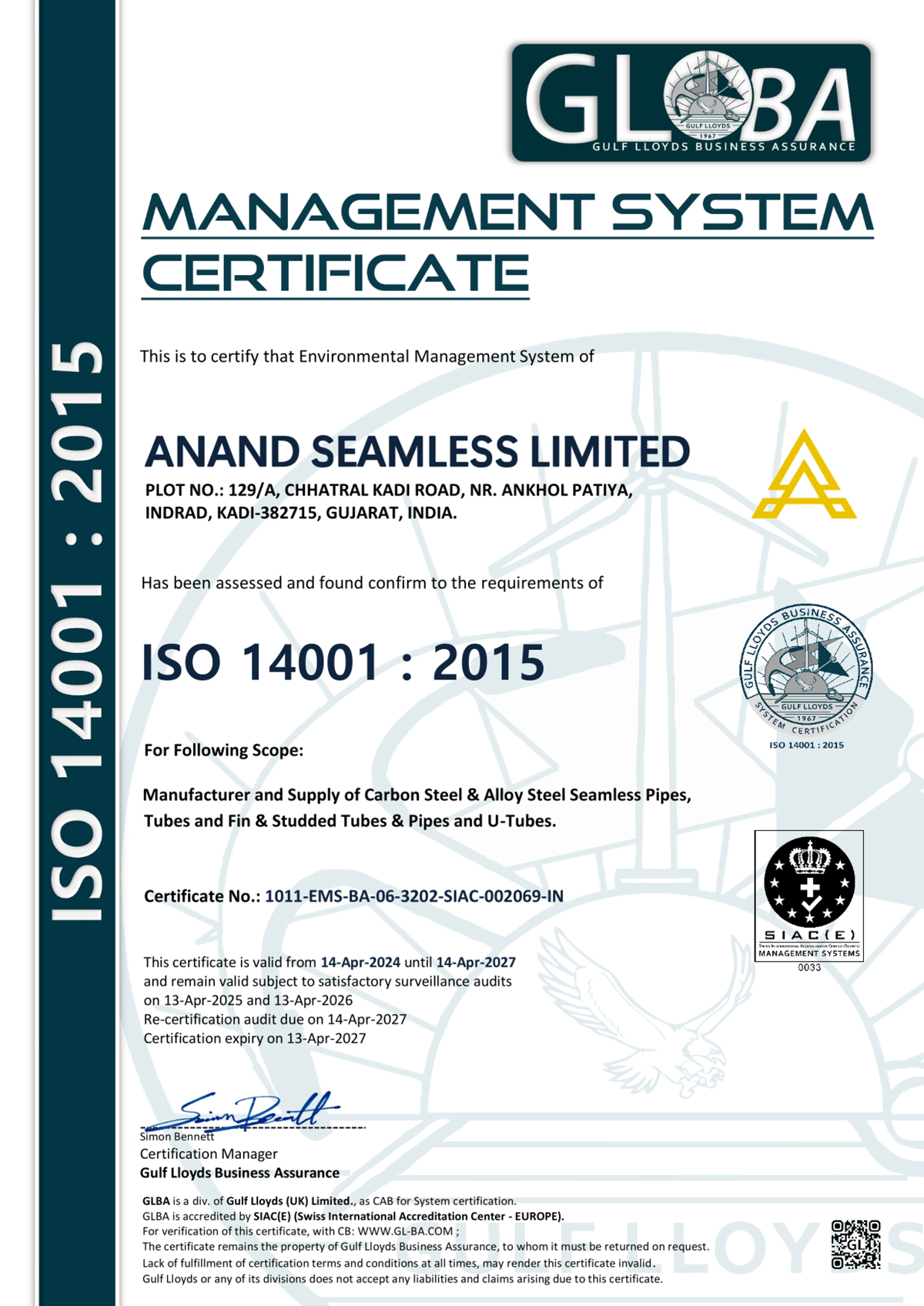

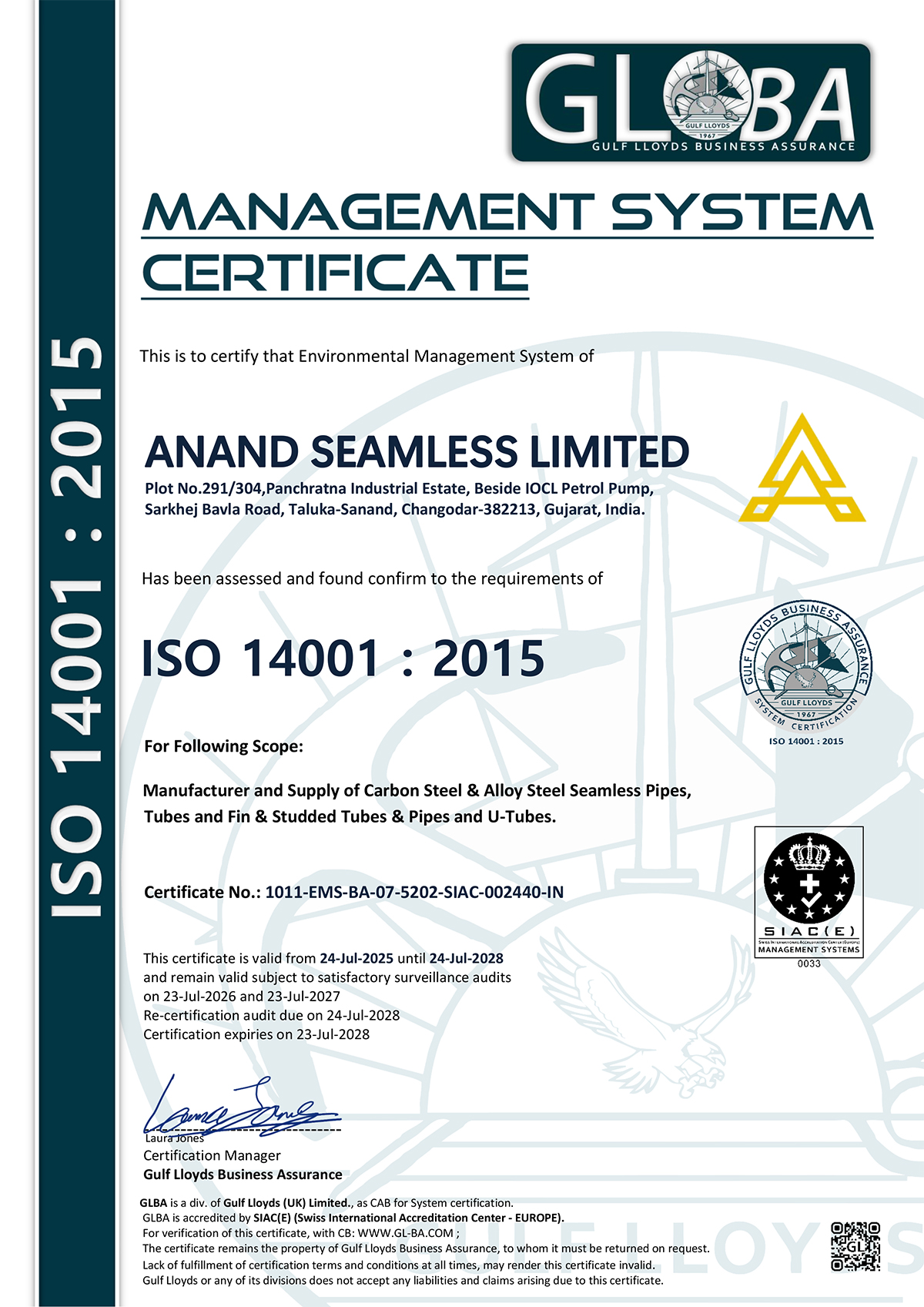

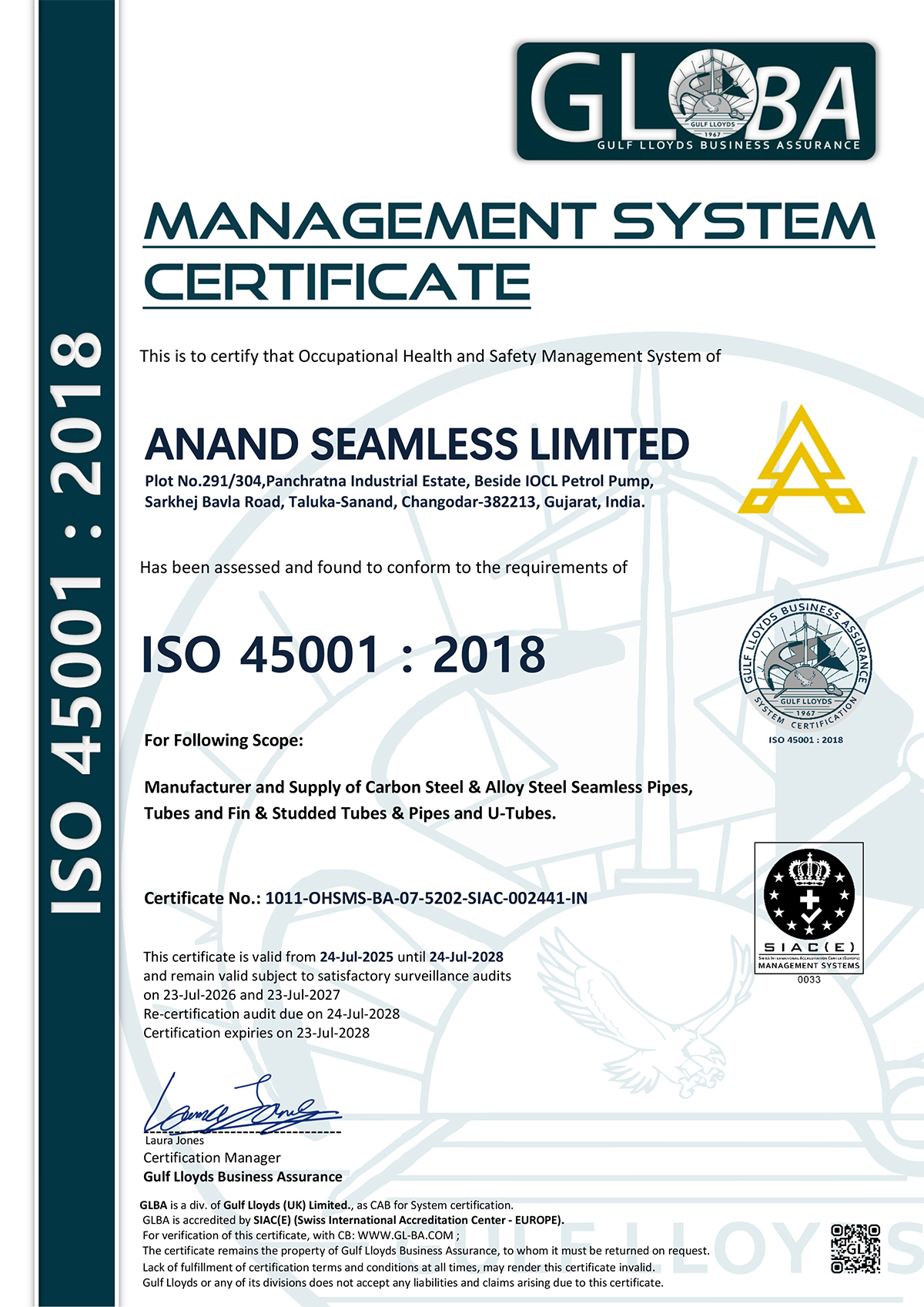

Quality & Certifications

Standard Check

Quality Management

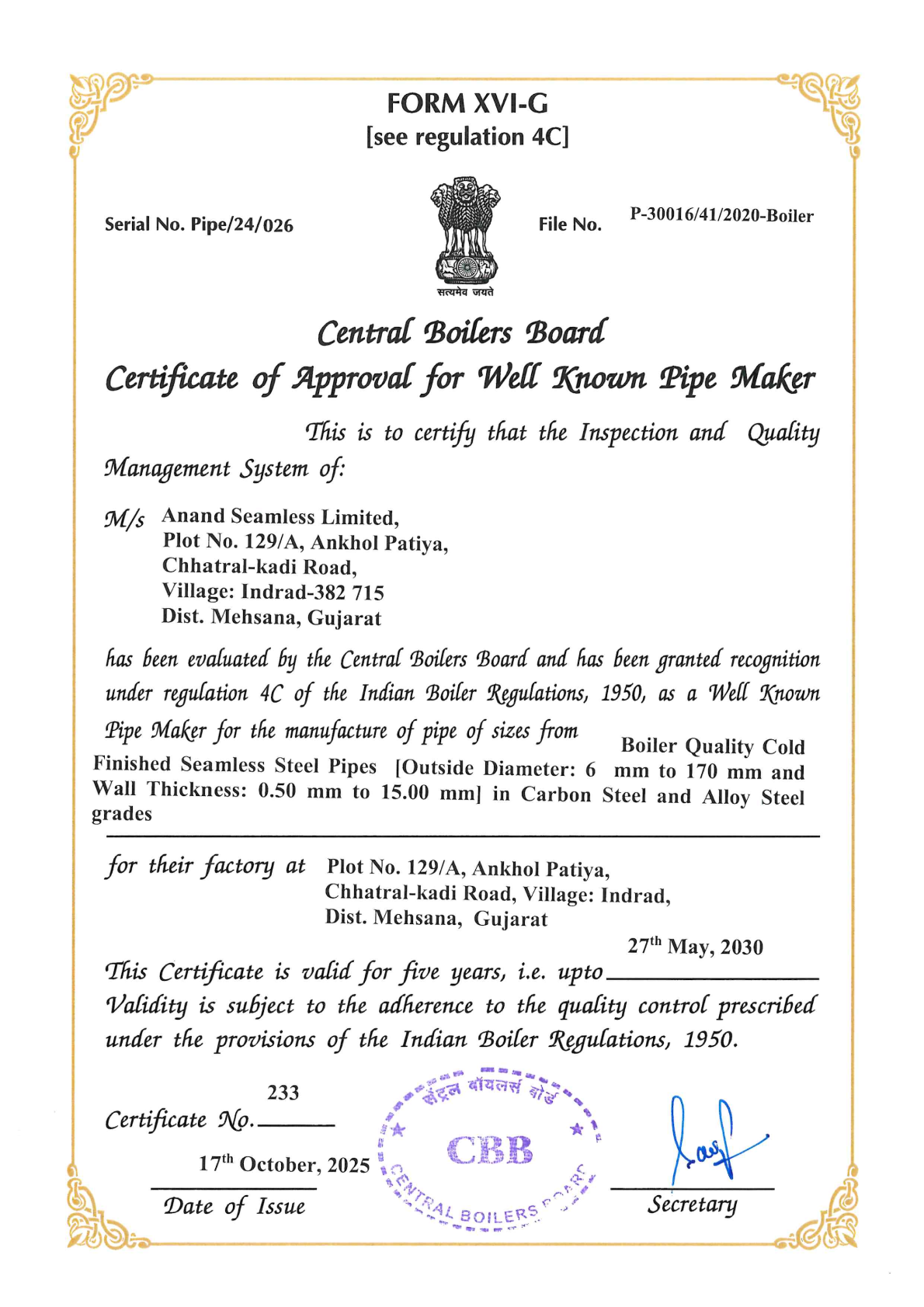

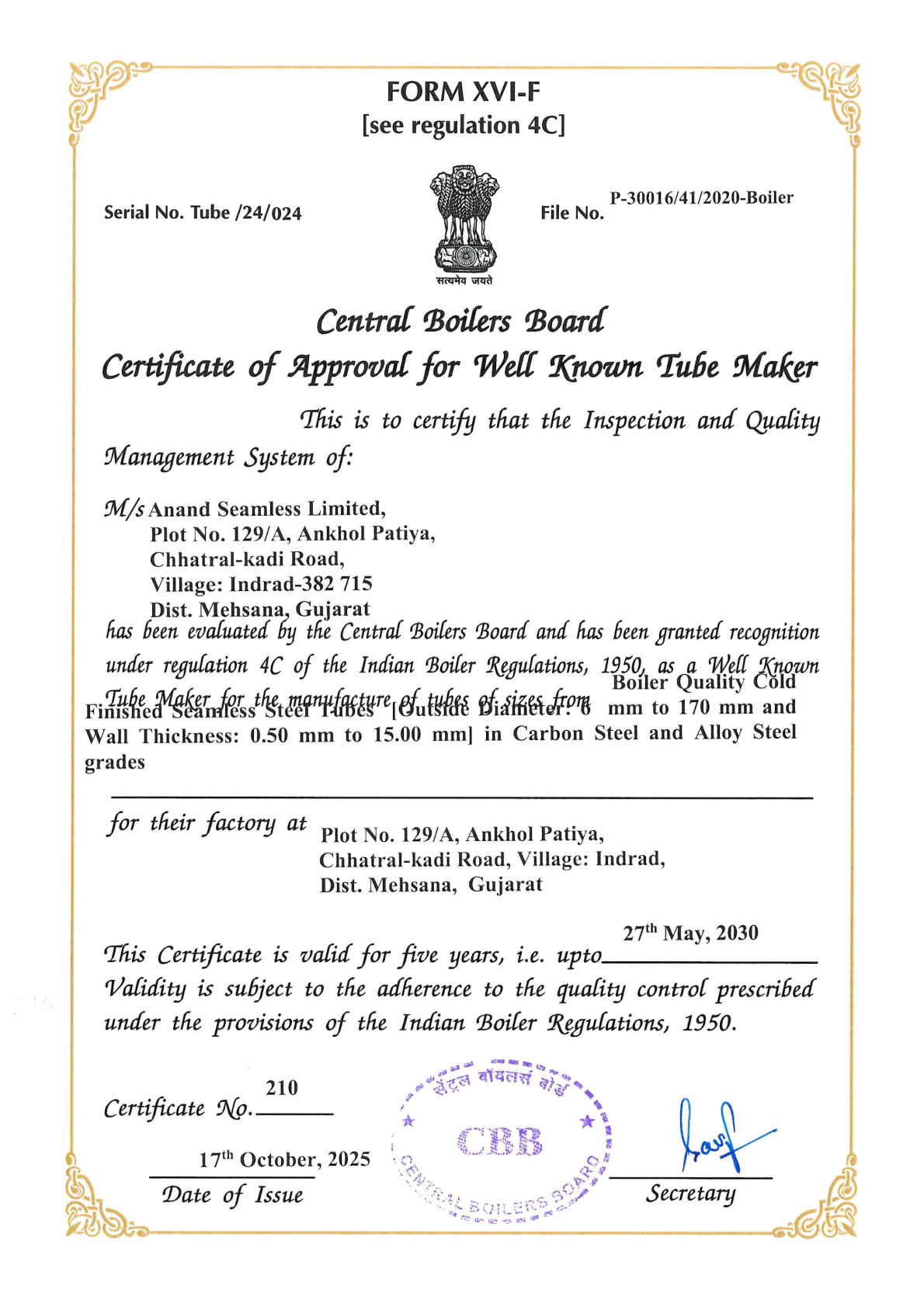

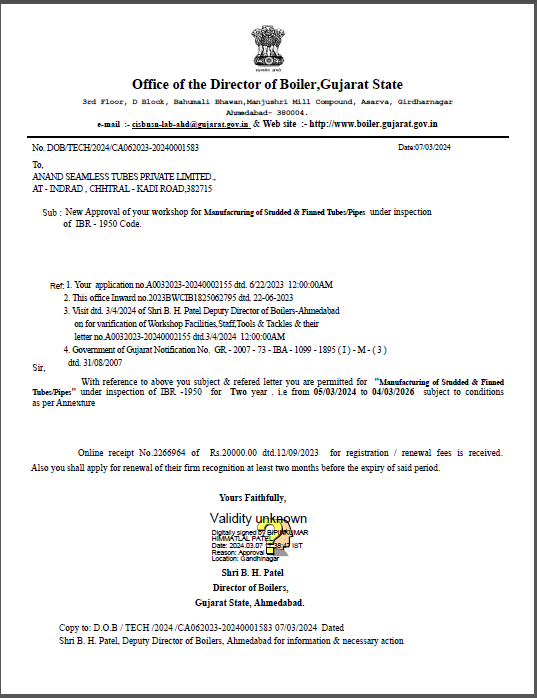

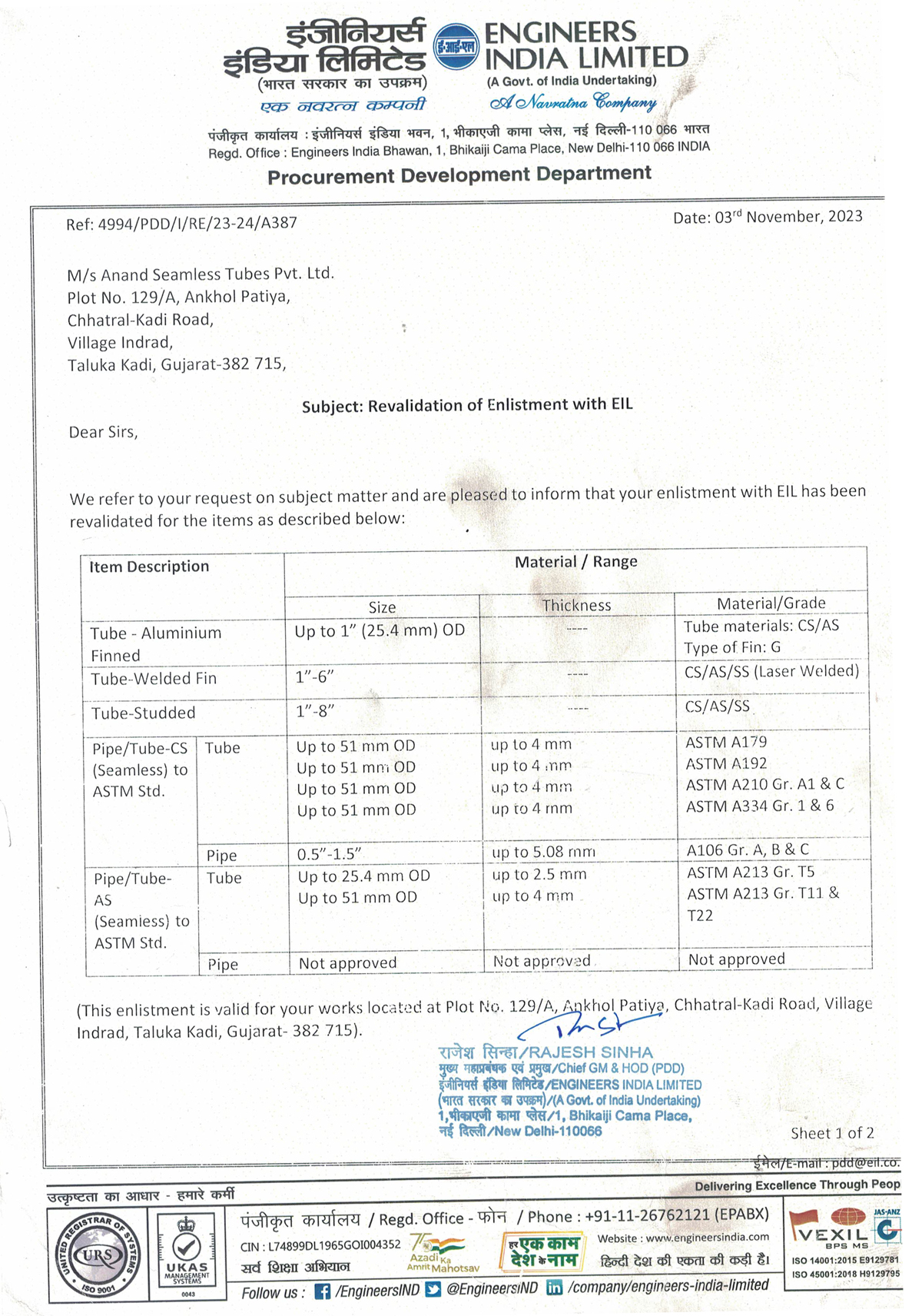

At Anand Seamless Ltd, quality has been given the highest importance. Our quality has been appreciated and approved by various national and international agencies.

100% material supplied from our plant carry a valid Mill Test Certificate as per E 10204 3.1 / 3.2 certification as required by the client. The products manufactured at our plants are regularly inspected and approved by renowned Third Party Inspection agencies like TUV, DNV, LLOYDS, BVIS ETC.

All the raw material used by Anand Seamless Ltd. are procured from approved standard quality suppliers. The quality assurance team ensures adherence to the QAP of manufacturing. Post receipt, all raw materials and consumables are inspected and tested.

At the production / manufacturing stage, Quality Control team conducts in-process inspection to ensure the standard / customer specific parameters adherence.

The Quality control test and checks are conducted regularly at each stage in order to maintain the uniform product quality.

Our in-house inspection uses the under mentioned test to ensure stringent quality standards.

|

NON DESTRUCTIVE TEST |

DESTRUCTIVE TEST |

|---|---|

| Eddy Current Test | Flaring Test |

| Hydrostatic Test | Hardness Test |

| Ultrasonic Testing | Flattening Test |

| Spectro Test | Corrosion Test |

| Visual Inspection | Impact/ Tensile Test |

| DP/MP Testing | “U” Bend mock up test |

| Boroscopic Test | Flange Test |

| IRIS Test | Bend Test |

| REFT Test | Reverse Flatteing / Bent Test |

| Micro Test | |

| Macro Test |

A typical cycle followed by Anand Seamless Ltd for Fin Tube/Pipe manufacturing include the following steps:

|

Stage |

Activity |

|---|---|

| RAW MATERIAL – BASE TUBE / PIPE | 100% inspection for MTC Traceability , confirmation with ordered grade, dimensional (sample) inspection |

| RAW MATERIAL –FIN MATERIAL | 100% inspection for MTC Traceability , confirmation with ordered grade, dimensional (sample) inspection |

| IN PROCESS INSPECTION | Random samples are checked to ensure that the technical requirements such as FPI , finned od , plain ends are meeting the client requirement |

| FINAL INSPECTION | 100 % tubes are checked for dimensional acceptance, visual appearance & traceability. |

| MILL TEST CERTIFICATE | Issued along with all the supplied material as per en 10204 3.1 / 3.2 norms. |