How Seamless Steel Pipes Ensure Safety in High‑Pressure Boiler Systems

When it comes to ensuring the safe operation of high-pressure boiler systems, the importance of selecting the right materials cannot be overstated. Among these materials, seamless steel pipes are a crucial choice due to their strength, durability, and performance under extreme conditions. In this blog post, we’ll explore why seamless steel pipes are essential in […]

read more

Why Seamless Tubes and Pipes Are Gaining Popularity in Heavy-Duty Industries

In the world of heavy-duty industries, where high performance, durability, and safety are paramount, the materials used for manufacturing equipment and piping systems need to meet exacting standards. Among the various materials available, seamless tubes and pipes have emerged as the preferred choice in numerous critical applications. From the oil and gas industry to power […]

read more

How Finned Tubes Help Combat Fouling in Heat Exchangers: Solutions for Clean Heat Transfer

Heat exchangers are the heart of many industrial systems, used to transfer heat between two or more fluids. However, one of the persistent challenges these systems face is fouling, the buildup of unwanted materials on heat exchanger surfaces. Finned tubes, commonly found in these systems, are no exception. While fouling in heat exchangers is a […]

read more

Custom Finned Tube Design for Concentrated Solar Power (CSP) Heat Exchangers

As India expands its renewable energy capacity, Concentrated Solar Power (CSP) plants are gaining serious attention. Unlike photovoltaic panels that directly convert sunlight to electricity, CSP systems use mirrors to concentrate sunlight onto receivers that heat a working fluid. This heat is then transferred to produce steam and generate electricity. At the heart of this […]

read more

Common Boiler Tube Failures and How to Prevent Them

Boilers are crucial components in many industrial settings, from power plants and manufacturing facilities to heating systems in residential and commercial buildings. Boiler tubes, often the heart of a boiler system, are responsible for conducting heat efficiently, transferring energy, and ensuring the system’s overall performance. However, like any machinery, they are prone to failures, which […]

read more

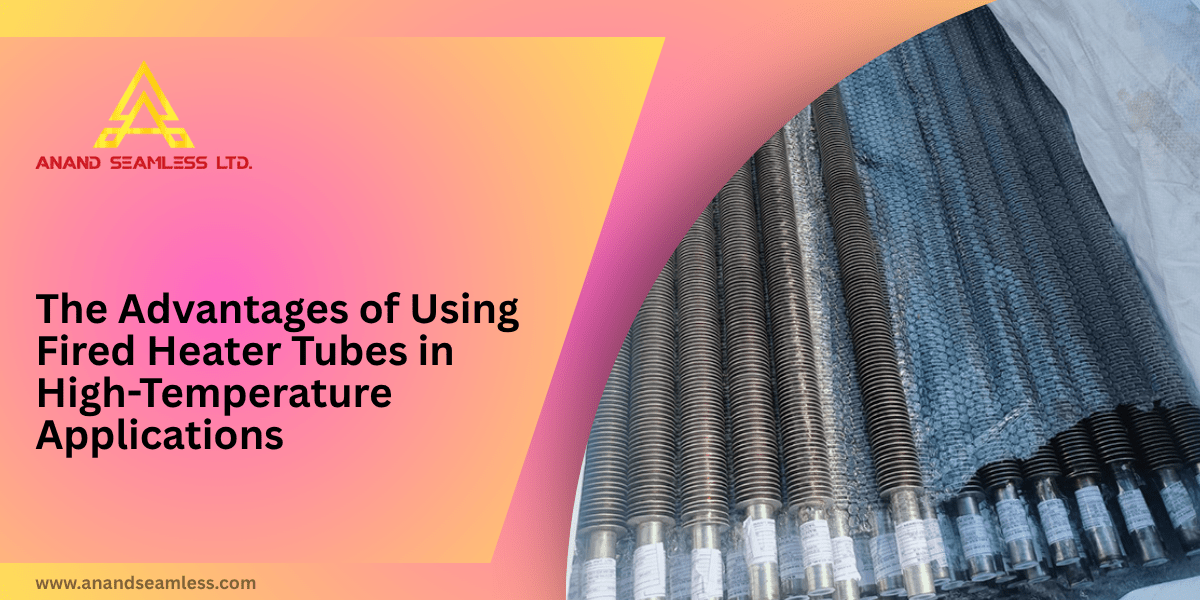

The Advantages of Using Fired Heater Tubes in High-Temperature Applications

In the world of industrial heating, efficiency, durability, and safety are paramount. Whether it’s refining oil, processing chemicals, or generating power, the role of heaters in industrial operations cannot be overstated. One key component that plays a vital role in ensuring effective heat transfer and system performance is the fired heater tubes. These specialised tubes […]

read more

How Indian Steel Pipe Manufacturers Are Driving the Growth of Smart Cities

India’s ambitious vision for smart cities is reshaping urban environments with cutting-edge technology, sustainable infrastructure, and better living conditions. As the country moves towards creating more efficient, connected, and sustainable cities, there is one critical element underpinning these developments: robust infrastructure. At the heart of every successful urban project is the reliable transportation of water, […]

read more

How to Choose the Right Grade of Alloy Steel Seamless Tube for Your Industry

In industrial operations, selecting the right alloy steel seamless tube is critical to ensure efficiency, durability, and safety. Businesses in sectors like oil & gas, power generation, chemical processing, and marine applications often face challenges when choosing the correct grade due to varying operational pressures, temperatures, and chemical exposures. Using the wrong grade can lead […]

read more

Finned Tubes in Harsh Environments: Best Practices for Longevity

Finned tubes are essential for enhancing heat transfer efficiency in industrial heat exchangers. They are designed to increase the surface area in contact with the fluid, optimising the heat exchange process. However, when used in high-dust or harsh environments, such as cement plants, mining operations, or offshore oil rigs, finned tubes face unique challenges that […]

read more