Quick Inquiry

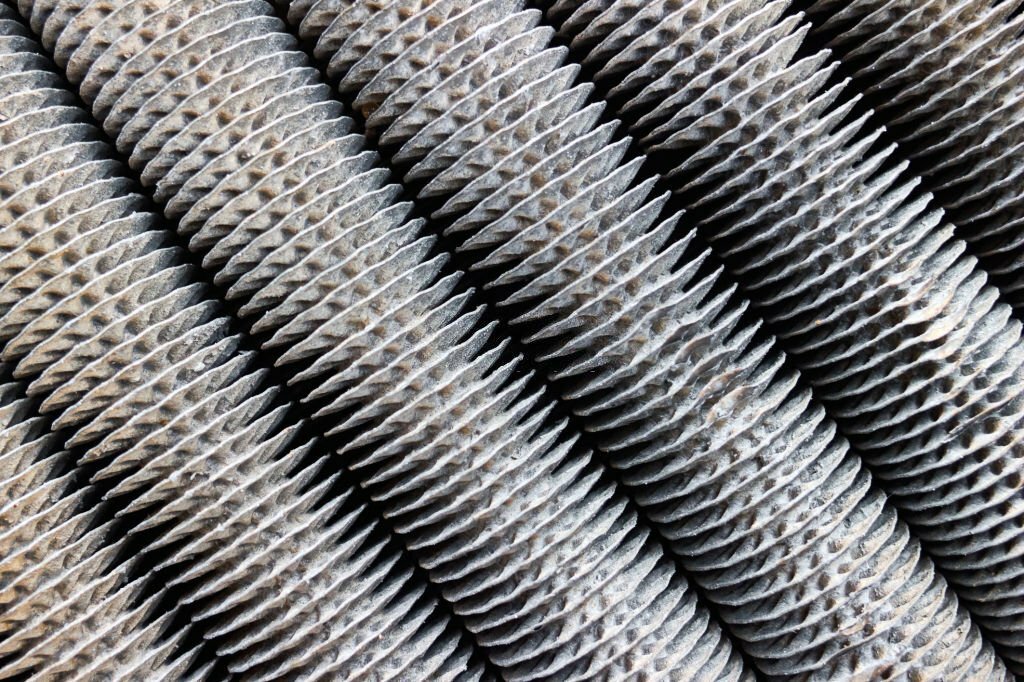

Efficient heat exchange is crucial in many industries, and finned tubes are essential components of heat transfer technology. For businesses, it’s important to have a nuanced understanding of the differences between high-fin tubes and low-fin tubes.

As one of the most trusted finned tube manufacturers and exporters in India, we have compiled this comprehensive guide that aims to provide detailed insights into the distinctive features and applications of these two types of tubes.

What Is the Difference Between High Fin Tube and Low Fin Tube

1. Fin Density

High Fin Tubes:

These exhibit a remarkable characteristic—higher fin density. The tightly packed fins create a labyrinth of surfaces, significantly amplifying the available area for heat transfer. This intricate design is invaluable in applications where optimising heat exchange efficiency is paramount.

Low Fin Tubes:

In contrast, low fin tubes boast a more relaxed fin density, with fins strategically spaced farther apart. This deliberate design choice reduces surface area, making these tubes ideal for scenarios where heat transfer efficiency is crucial but doesn’t demand the highest possible density.

2. Heat Transfer Efficiency

High Fin Tubes:

The heightened fin density of high fin tubes directly translates to superior heat transfer efficiency. This feature is particularly advantageous in applications where precision temperature control or exceptional thermal performance is non-negotiable.

Low Fin Tubes:

While still delivering effective heat transfer, low-fin tubes cater to scenarios where the demand for enhanced efficiency is not as critical. Applications in the food and beverage industry, for instance, often find these tubes suitable, where maintaining a consistent temperature is essential, but not necessarily at peak efficiency levels.

3. Surface Area-to-Volume Ratio

High Fin Tubes:

The intensified fin density of high fin tubes contributes to an elevated surface area-to-volume ratio. This architectural feature enhances heat dissipation, rendering these tubes well-suited for applications where managing high temperatures is a primary concern.

Low Fin Tubes:

Conversely, low fin tubes, characterised by a more modest fin density, exhibit a comparatively lower surface area-to-volume ratio. This design makes them apt for applications where moderate heat transfer is sufficient and considerations such as cost-effectiveness take precedence.

4. Applications

High Fin Tubes:

Process Industries: Chemical and petrochemical sectors leverage high fin tubes’ enhanced heat transfer capabilities for optimal performance in their processes.

Power Generation: They are pivotal in power plants, optimising heat exchanger efficiency and contributing to energy production.

HVAC Systems: They find a natural home in HVAC systems, ensuring top-tier thermal performance for heating, ventilation, and air conditioning applications.

Low Fin Tubes:

Food and Beverage: Low-fin tubes prove invaluable in industries where precise temperature control is paramount for food and beverage production processes.

General HVAC: They offer a cost-effective yet reliable solution in HVAC applications where maximising efficiency is not the primary concern.

Do High Fin Tubes and Low Fin Tubes Use Different Materials?

High-fin tubes and low-fin tubes can be made from the same or different materials depending on their application requirements. Both are crafted with precision, and the selection of materials can significantly impact their performance in diverse industrial applications.

High Fin Tubes:

They are designed for applications demanding top-tier heat transfer efficiency and are often crafted from materials prioritising conductivity and durability. Common materials include high-grade stainless steel and alloys, ensuring resistance to corrosion and high-temperature environments. The meticulous engineering of high fin tubes focuses on the fin density and extends to the material composition, guaranteeing optimal performance in challenging conditions.

Low Fin Tubes:

Similarly, low fin tubes are tailored to meet the demands of applications where efficient heat transfer is essential but don’t require the heightened performance of high fin tubes. Materials like carbon steel and other cost-effective alloys are often chosen for crafting low-fin tubes. This strategic material selection ensures a balance between performance and affordability, making low-fin tubes a practical choice for industries prioritising economical solutions without compromising functionality.

Optimising Efficiency: Practical Considerations for Businesses

Beyond the nuanced differences in fin density and material composition between high fin tubes and low-fin tubes, businesses operating these tubes must also consider practical aspects to optimise efficiency in their applications.

Maintenance and Cleaning:

High-fin tubes, with their intricate designs, may require more attention to maintenance and cleaning. The closely spaced fins, while providing enhanced heat transfer, can also be susceptible to fouling and debris accumulation. Regular maintenance routines, including cleaning protocols, become crucial to ensure the longevity and sustained efficiency of high-fin tubes. With their more spaced-out fins, low-fin tubes might present a more straightforward maintenance profile.

Cost Considerations:

While high-fin tubes offer unparalleled heat transfer efficiency, businesses must weigh the benefits against the associated costs. The premium materials and complex manufacturing processes of the tubes contribute to higher upfront costs. Low-fin tubes, designed for cost-effectiveness, may prove more suitable for applications where the highest efficiency is not a primary requirement, allowing businesses to strike a balance between performance and budget considerations.

Customisation for Specific Applications:

Finned tube manufacturers understand that every industry and application is unique. Offering customisation options for both high and low-fin tubes allows businesses to tailor these components to their specific needs. Whether adjusting the fin density, selecting specific materials, or incorporating unique dimensions, customisation ensures that fin tubes seamlessly integrate into diverse industrial processes.

Frequently Asked Questions

1. Are high-fin tubes more expensive than low-fin tubes?

Yes, high-fin tubes typically come with higher upfront costs due to premium materials and intricate manufacturing processes. However, businesses should consider the long-term benefits of enhanced efficiency and performance.

2. Do low fin tubes compromise heat transfer efficiency?

While low fin tubes have a lower fin density than high fin tubes, they still offer effective heat transfer. They are ideal for applications where the absolute highest efficiency is not a primary requirement, making them a cost-effective solution.

3. How can businesses determine the right fin density for their applications?

The choice of fin density depends on the specific heat transfer requirements of the application. High-fin tubes, with their closely spaced fins, are ideal for applications demanding top-tier efficiency, while low fin tubes, with more spaced-out fins, suit scenarios where efficient heat transfer is crucial but not at the highest level. It also helps to consult the right manufacturer to get expert recommendations.

4. Are customisation options available for high and low fin tubes?

Yes, finned tube manufacturers in India often provide customisation options for both high fin tubes and low-fin tubes. This may include adjusting fin density, selecting specific materials, or incorporating unique dimensions to meet the diverse needs of different applications.

5. Can low-fin tubes be used in precise temperature control applications?

Yes, low fin tubes are suitable for applications requiring efficient heat transfer and moderate temperature control. Industries like food and beverage, where consistent temperatures are essential, often find low-fin tubes to be a practical and cost-effective solution.

6. How do budget constraints influence the choice between high fin tubes and low-fin tubes?

Budget constraints play a significant role in the decision-making process. While high fin tubes offer superior performance, businesses must weigh the benefits against the higher upfront costs. Low-fin tubes provide a more economical choice without compromising functionality, making them suitable for budget-conscious projects.

7. Can finned tube manufacturers provide guidance on the most suitable option for specific applications?

Yes, experienced finned tube manufacturers in India often collaborate with businesses to understand their specific needs and recommend the most suitable option. This may involve considering heat transfer requirements, budget constraints, and long-term maintenance considerations.

We Offer Different Types of Fin Tubes as Exporters and Manufacturers in India

We make it easy for you to achieve exceptional thermal efficiency with our seamless tubes. Our company is a top manufacturer and exporter of fin tubes in India. We take pride in providing custom-tailored excellence to meet your specific needs. Our products are engineered to enhance your industrial processes, no matter where you are located. We offer a diverse range of finned tubes that are designed to meet the requirements of our clients in the USA, Spain, the UK, Dubai, Germany, Italy, Kuwait, Oman, and Qatar.

With our precision engineering and high-quality materials, you can experience the difference that optimized heat transfer can make in enhancing your operations. We specialize in customizing solutions that align seamlessly with your requirements, from high-fin tubes for top-tier performance to cost-effective, low-fin tubes. Our range of tubes meets international standards, ensuring that you receive only the best quality products for your industrial processes.

At Anand Seamless Ltd, we understand that every business has specific requirements, and we take pride in offering cutting-edge solutions designed to enhance your thermal efficiency, ensuring a seamless experience.

Contact us at +91-9099996853 or write to us at inquiry@anandseamless.com (India) or biz@anandseamless.com (International) to explore how our solutions can elevate your operations and optimize your thermal efficiency. We will be happy to assist you.

Also Read: A Complete Guide to Different Types of Finned Tubes

lATEST BLOG |

|

Top Industrial Applications of Extruded Fin Tubes

Finned tubes are the unsung heroes of thermal syst |

|

The Rise of Finned Copper Tubes in High-Performance Cooling Systems

In today’s fast-paced world of industrial in |

|

Role of Finned Tubes in Waste Heat Recovery Systems

In today’s industrial world, where energy effici |

|

Why Cold-Drawn Tubes Are Ideal for High-Pressure Applications

In industries where materials are pushed to the ed |

|

Common Seamless Tube Defects and How Manufacturers Prevent Them

Seamless tubes are the backbone of many critical a |