Quick Inquiry

Mechanical tubes form the backbone of various industrial applications, ranging from automotive to construction. As a business operating in these sectors, it’s crucial to understand how enhancing the tubes can lead to improved performance and efficiency in your applications.

In this guide, we’ll explore various techniques and methods to enhance mechanical tubes for different industries. We’ll delve into tips specifically tailored for the automotive and construction sectors, providing valuable insights to optimise your operations.

Tips to Improve Mechanical Tubes for the Automotive Industry

Cutting:

Precision cutting is essential to ensure the desired length and shape of mechanical tubes for automotive applications. Utilising advanced cutting techniques such as laser cutting or abrasive cutting can enhance accuracy and efficiency. Additionally, employing automated cutting processes can significantly reduce production time and minimise material waste, ultimately improving cost-effectiveness.

Plating:

Surface protection is paramount in the automotive industry to enhance the corrosion resistance and durability of mechanical tubes. Electroplating techniques, such as zinc plating or chrome plating, can provide a protective layer that shields tubes from environmental factors and extends their lifespan. Moreover, choosing the appropriate plating material based on the application’s requirements ensures optimal performance under various conditions.

Machining:

Precision machining plays a crucial role in refining the dimensional accuracy and surface finish of mechanical tubes for automotive components. CNC machining technologies enable intricate shaping and drilling operations with high repeatability, ensuring consistency in product quality. By investing in advanced machining processes, businesses can achieve tighter tolerances and meet stringent automotive specifications, enhancing overall product performance and reliability.

Tips to Improve Mechanical Tubes for the Construction Industry

Powder Coating:

Powder coating offers a versatile and durable finishing solution for mechanical tubes used in construction applications. This method involves electrostatically applying dry powder to the surface of the tubes, which is then cured to form a protective coating. Powder coating provides excellent resistance to corrosion, UV exposure, and abrasion, making it ideal for outdoor structures and architectural elements. Additionally, the wide range of available colours allows for customisation to suit specific aesthetic requirements.

Drilling:

Precise drilling of mechanical tubes is essential for accommodating fasteners, connectors, and structural components in construction projects. Utilising advanced drilling equipment, such as CNC drilling machines, ensures accurate hole placement and dimensionality, facilitating seamless assembly and installation processes. Whether it’s for scaffolding, framework, or support structures, precise drilling enhances the functionality and structural integrity of these tubes in construction applications.

Galvanising:

Galvanisation is a highly effective method for protecting mechanical tubes against corrosion in harsh environments encountered in construction sites. By immersing tubes in molten zinc or applying a zinc coating through electroplating, galvanising creates a robust barrier that prevents corrosion and extends the service life of the tubes. Galvanised tubes are widely utilised in applications such as fencing, handrails, and structural frameworks, where durability and longevity are paramount.

Tips to Improve Mechanical Tubes for the Aerospace Industry

Heat Treatment:

In the aerospace industry, mechanical tubes often undergo extreme conditions during flight, including high temperatures and pressure differentials. Heat treatment plays a critical role in enhancing the mechanical properties and structural integrity of tubes to withstand these demanding environments. Processes such as annealing, quenching, and tempering help optimise the microstructure of the material, improving its strength, hardness, and ductility. Additionally, specialised heat treatment techniques like solution treatment and ageing can further enhance the performance of alloys used in aerospace applications, ensuring reliability and safety under extreme operating conditions.

Testing:

Rigorous testing is essential to ensure the quality and performance of mechanical tubes for aerospace applications, where even the slightest defect can have catastrophic consequences. Non-destructive testing (NDT) methods such as ultrasonic testing, eddy current testing, and radiographic inspection are commonly employed to detect flaws, cracks, or irregularities in the tubes without causing damage. These advanced testing techniques allow manufacturers to identify potential defects early in the production process, enabling corrective measures to be taken promptly to maintain the highest standards of safety and reliability in aerospace components.

Tips to Improve Mechanical Tubes for the Agriculture Industry

Turning:

Turning is a fundamental machining process to achieve precise dimensional accuracy and surface finish on mechanical tubes for various agricultural applications. Whether it’s manufacturing irrigation systems, crop harvesting equipment, or livestock handling machinery, turning operations help achieve the desired geometry and surface characteristics of tubes. Computer numerical control (CNC) turning machines enable efficient and high-precision turning processes, allowing for tight tolerances and consistent quality in agricultural tube components. By optimising turning operations, manufacturers can enhance the performance and longevity of tubes used in agricultural machinery, contributing to increased productivity and efficiency in farming operations.

Boring and Honing:

Boring and honing are essential processes for refining the internal surfaces of mechanical tubes used in agricultural equipment, such as hydraulic cylinders, pumps, and tractor components. Boring enlarges existing holes or cavities in the tubes to accommodate bearings, seals, or other components, while honing improves surface finish and dimensional accuracy, ensuring proper fit and functionality. Advanced honing techniques, such as abrasive honing and diamond honing, provide superior surface quality and tight tolerances required for critical agricultural applications. By employing precise boring and honing processes, manufacturers can optimise the performance and reliability of the tubes in agricultural machinery, enhancing overall equipment efficiency and durability in demanding farming environments.

What Is Mechanical Tube Honing?

Mechanical tube honing is a precision machining process used to improve the internal surface finish and dimensional accuracy of cylindrical tubes. Unlike traditional machining methods like drilling or boring, honing achieves superior surface quality by removing minute imperfections and irregularities through a controlled abrasive action. This process is particularly crucial for applications where tight tolerances, smooth surface finishes, and optimal performance are essential, such as hydraulic cylinders, pneumatic systems, and precision machinery components.

How Does Mechanical Tube Honing Work?

Mechanical tube honing involves passing a specialised honing tool through the interior of the tube while simultaneously rotating and reciprocating it. The honing tool consists of abrasive stones or diamond grit bonded to a metal mandrel, which conforms to the inner diameter of the tube. As the tool moves back and forth within the tube, it abrades the surface, gradually removing material and smoothing out imperfections. The rotational and reciprocating motion ensures uniform material removal across the entire length of the tube, resulting in a consistent surface finish.

Frequently Asked Questions

What is the difference between honing and boring?

While both honing and boring are machining processes used to improve the internal surface of cylindrical tubes, honing focuses on achieving a finer surface finish and tighter dimensional tolerances compared to boring. Honing utilises abrasive stones or diamond grit to remove material incrementally, resulting in a smoother surface texture, whereas boring enlarges existing holes or cavities without necessarily improving surface finish.

Is mechanical tube honing suitable for all materials?

Mechanical tube honing is compatible with a wide range of materials, including steel, stainless steel, aluminium, brass, and various alloys. However, the specific honing process parameters may vary depending on the material’s hardness, ductility, and other properties.

Can honing be used to correct out-of-roundness in mechanical tubes?

Yes, mechanical tube honing can help correct minor deviations from roundness by removing material selectively from high points on the inner surface. However, significant out-of-roundness may require additional machining operations or material removal techniques.

What are the typical applications of honed mechanical tubes?

Honed mechanical tubes find applications in hydraulic cylinders, pneumatic systems, precision machinery components, automotive engine cylinders, and firearm barrels, among others. The smooth surface finish and precise dimensional control achieved through honing are critical for ensuring optimal performance and longevity in these applications.

Is mechanical tube honing a cost-effective process?

While mechanical tube honing may involve higher initial setup costs compared to traditional machining methods, its benefits in terms of improved surface finish, dimensional accuracy, and component longevity often outweigh the upfront expenses. Additionally, the efficiency and consistency of honing processes contribute to long-term cost savings by reducing maintenance requirements and downtime in industrial operations.

No Matter Your Challenges We Offer Customised Mechanical Tubes

Anand Seamless Ltd. is a trusted supplier of mechanical tubing solutions for diverse industries. We understand the complexities and unique requirements of each project. Whether you’re in the automotive, aerospace, construction, agriculture, or any other industry, we’re committed to delivering top-quality mechanical tubes tailored to your specific needs.

We offer an extensive range of tubes that conform to international standards, including EN 10305-1 E 215, E 235, and E 355, as well as DIN 2391 ST 35, ST 45, and ST 52. We adhere to stringent standards so you can trust that our products meet the highest quality and performance benchmarks.

Partner with us, and experience the difference that personalised solutions can make for your business. No matter the complexity of your requirements, we have the expertise, resources, and dedication to provide you with the ideal mechanical tubing solution.

Contact us today at +91-9909968550 (India) or +91-9099996853 (International) to discuss your

project needs and discover how we can help you achieve your goals. We will be happy to assist you in providing seamless tubes or mechanical tubes as per your business requirements.

lATEST BLOG |

|

How to Choose Right Grade Carbon Steel Seamless Tubes

Carbon steel seamless tubes are essential componen |

|

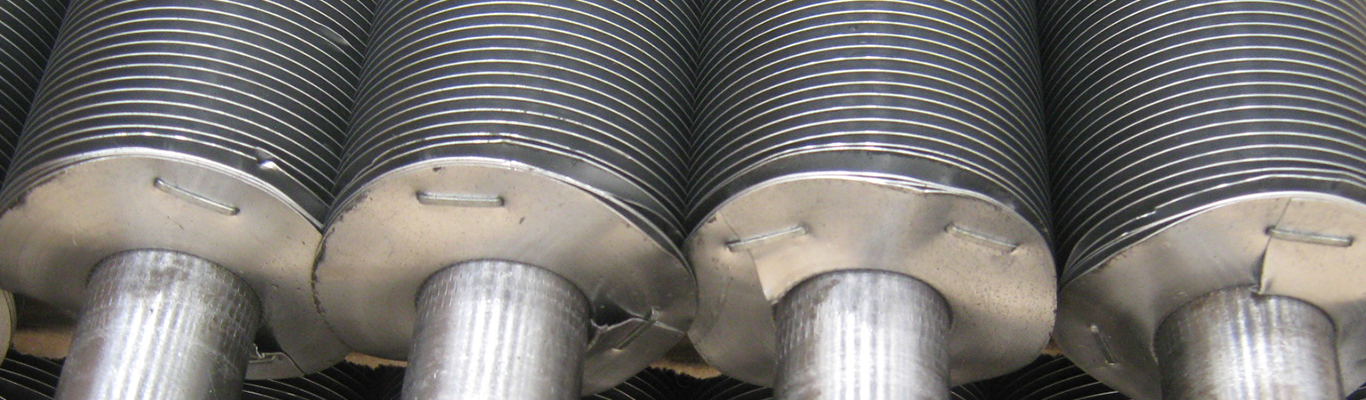

Basics of Aluminum Finned Tubes

In the world of heat exchange technology, aluminiu |

|

How to Enhance Mechanical Tubes for Various Applications

Mechanical tubes form the backbone of various indu |

|

Why Are U-Tube Heat Exchangers Undeniably Vital: A Complete Guide

In the landscape of industrial heat exchange syste |

|

Introductory Guide to Economizer Tubes

In the dynamic landscape of industrial operations, |