Quick Inquiry

Air fin cooler tubes are a crucial part of industrial heat exchange systems. To understand the significance of these tubes, it is essential to delve into their intricate workings, applications, and the pivotal role they play in various industrial sectors. Whether you are an experienced industry player or someone who is exploring new avenues for enhancing your thermal management systems, our comprehensive guide on air fin cooler tubes aims to provide you with invaluable insights into this important component.

What Are Air Fin Cooler Tubes

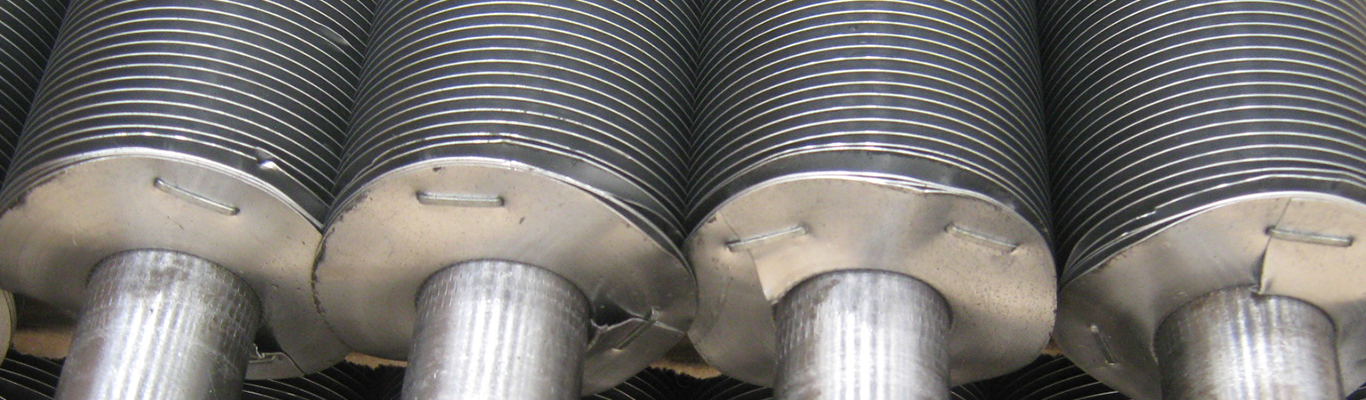

Air fin cooler tubes, also recognised as finned tubes or fin tube heat exchangers, represent a pinnacle in heat transfer engineering. These specialised tubes are meticulously engineered with extended surfaces, or fins, adorning their lengths, thereby substantially amplifying the available surface area for heat exchange processes.

At their core, these tubes are designed to facilitate the seamless transfer of heat between a fluid coursing within the tube and the ambient air enveloping it. This fundamental function finds application across many industries, from the petrochemical and power generation sectors to the HVAC and refrigeration domains.

Crafted from various materials, including stainless steel, carbon steel, copper, or aluminium, air fin cooler tubes are tailored to suit the unique demands of diverse applications. The intricate integration of fins onto the outer surface of the tube, employing techniques such as extrusion, roll forming, or welding, exemplifies the meticulous engineering prowess behind these tubes.

Typical Components of Air Fin Cooler Tubes

Air fin cooler tubes comprise several essential components that contribute to their efficient operation and heat exchange capabilities. Understanding these components is crucial for businesses seeking to optimise their thermal management systems. Here are the typical components of the tubes:

Tube Base Material

The primary structure of the tubes is crafted from materials such as stainless steel, carbon steel, copper, or aluminium. The choice of material depends on factors such as corrosion resistance, thermal conductivity, and operational environment.

Fins

Fins are the defining feature of these tubes. These extended surfaces are attached to the outer surface of the tube and significantly increase the surface area available for heat exchange. Fins are often made from the same material as the tube base or specialised alloys to enhance heat transfer efficiency.

Finned Tube Assembly

The process of attaching fins to the tube base can vary depending on the manufacturing method. Common techniques include extrusion, roll forming, or welding. Each method offers distinct advantages in cost-effectiveness, durability, and precision.

Headers

Headers are integral components that facilitate the connection of multiple finned tubes within an air fin cooler assembly. These headers provide entry and exit points for the fluid flowing through the tubes, ensuring efficient heat exchange across the entire system.

Support Structures

To maintain structural integrity and prevent sagging or deformation, air fin cooler tubes may feature support structures such as braces, brackets, or grids. These components help distribute the weight of the tubes and ensure stability during operation.

Corrosion Protection

Depending on the operating environment and fluid composition, these tubes may require additional corrosion protection measures. This can include surface coatings, sacrificial anodes, or specialised alloy compositions to prolong the lifespan of the tubes and maintain optimal performance.

Mounting Hardware

Mounting hardware such as bolts, nuts, and flanges are used to secure the tubes within the heat exchanger assembly. Proper installation and fastening of these components are essential to prevent leaks and ensure efficient heat transfer.

Design Features

The design of air fin cooler tubes is critical in determining their performance, durability, and suitability for specific applications. Here are key design features to consider:

Fin Density and Configuration

The density and configuration of fins on the tubes significantly impact heat transfer efficiency. Higher fin density increases surface area but may lead to higher pressure drop and airflow resistance. Engineers must balance these factors to optimise performance.

Tube Geometry

The geometry of the tube, including diameter, length, and wall thickness, influences fluid flow dynamics and heat transfer characteristics. Design considerations such as Reynolds number, Prandtl number, and Nusselt number are essential for optimising tube geometry.

Airflow Distribution

Proper airflow distribution across the finned surface is crucial for uniform heat transfer. Design features such as fan placement, baffle arrangements, and ducting configurations help optimise airflow distribution and minimise hot spots or cold zones.

Heat Transfer Enhancement

Various techniques, such as turbulators, vortex generators, and surface enhancements, can be incorporated into the design of air fin cooler tubes to enhance heat transfer performance. These features disrupt boundary layers and promote more efficient heat exchange.

Thermal Expansion Considerations

Differential thermal expansion between the tube material and the fins can lead to mechanical stresses and potential failure. Design features such as expansion joints or flexible connections accommodate thermal expansion and contraction, ensuring long-term reliability.

Maintenance Accessibility

Design features that facilitate ease of maintenance and inspection, such as removable access panels or modular construction, can reduce downtime and operational costs over the lifespan of the tubes.

Environmental Considerations

Factors such as ambient temperature, humidity, and airborne contaminants can impact the performance and longevity of air fin cooler tubes. Design features that mitigate corrosion, fouling, and environmental degradation are essential for ensuring reliable operation in harsh conditions.

Applications

Air fin cooler tubes find wide-ranging applications across diverse industries, owing to their versatility, efficiency, and reliability in heat exchange processes. Here are some key applications:

Petrochemical Industry

The tubes are extensively used in the petrochemical industry to cool various process fluids such as crude oil, natural gas, and petrochemical derivatives. These tubes are crucial in maintaining optimal temperatures during refining, processing, and transportation operations.

Power Generation

In power plants, air fin cooler tubes are utilised in the cooling systems of steam turbines, condensers, and heat exchangers. They help dissipate heat generated during electricity generation processes, ensuring efficient operation and prolonging equipment lifespan.

HVAC (Heating, Ventilation, and Air Conditioning)

These tubes are integral components in HVAC systems for both residential and commercial buildings. They facilitate heat exchange between refrigerants and ambient air, enabling effective heating and cooling to maintain comfortable indoor environments.

Refrigeration

Air fin cooler tubes are employed in refrigeration systems for the condensation of refrigerants and the dissipation of heat from compressors and condensers. These tubes contribute to efficiently operating refrigeration units in supermarkets, cold storage facilities, and industrial refrigeration plants.

Chemical Processing

In chemical processing plants, these tubes are utilised for cooling process fluids in various chemical reactions and manufacturing processes. They play a critical role in controlling temperatures to ensure product quality, safety, and process efficiency.

Oil and Gas Industry

These tubes are indispensable in the oil and gas industry for the cooling of drilling fluids, hydraulic systems, and equipment used in exploration, production, and transportation operations. They help prevent equipment from overheating and maintain operational integrity in harsh environmental conditions.

Food and Beverage Industry

Air fin cooler tubes are employed in the food and beverage industry for applications such as pasteurisation, sterilisation, and cooling of food products and processing equipment. They contribute to maintaining hygiene standards, extending shelf life, and ensuring product quality and safety.

Frequently Asked Questions

How do these air fin cooler tubes enhance heat transfer?

The tubes feature extended surfaces, or fins, along their lengths, which significantly increase the surface area available for heat exchange. This enlarged surface area improves heat transfer efficiency by promoting greater contact between the fluid and the surrounding air.

What are the typical materials used in manufacturing the tubes?

Air fin cooler tubes are crafted from materials such as stainless steel, carbon steel, copper, or aluminium, selected based on factors such as corrosion resistance, thermal conductivity, and operational environment. The fins may also be made from the same material as the tube or from specialised alloys to enhance heat transfer efficiency.

What are the key considerations when selecting air fin cooler tubes for specific applications?

When choosing these tubes, factors such as operating temperature, fluid composition, pressure requirements, space constraints, and environmental conditions must be taken into account. Additionally, considerations regarding tube geometry, fin density, and airflow distribution play crucial roles in optimising performance.

How do these tubes compare to traditional water-cooled systems?

Air fin cooler tubes offer several advantages over traditional water-cooled systems, including lower operating costs, reduced water consumption, greater flexibility in installation, and suitability for applications where water availability or quality is limited. Additionally, air-cooled systems eliminate the risk of water contamination or leakage.

What maintenance practices are recommended for air fin cooler tubes?

Regular maintenance practices such as cleaning, inspection, and monitoring of airflow and fluid parameters are essential for ensuring the optimal performance and longevity of the tubes. Cleaning may involve removing debris, fouling, or corrosion from the tube surface, while inspection helps detect any signs of damage or degradation that could affect performance. Additionally, monitoring fluid parameters such as temperature, pressure, and flow rate enables timely adjustments and preventative maintenance measures.

Invest in High Quality & Durable Air Fin Cooler Tubes

Anand Seamless Ltd is a leading finned tubes and heat exchanger tubes manufacturer in India. Invest in high-quality and durable air fin cooler tubes with us to elevate your industrial processes to new heights of efficiency and reliability. With our meticulously crafted tubes engineered to withstand the most demanding operating conditions, you can ensure optimal heat transfer performance and prolonged equipment lifespan.

Don’t settle for subpar solutions that compromise on quality and reliability. At Anand Seamless Ltd, we manufacture air fin cooler tubes utilising top-grade materials and innovative design features to deliver unparalleled performance and value.

Take the first step towards enhancing your thermal management systems and maximising operational efficiency. Invest in our high-quality seamless tubes and experience the difference firsthand. Your satisfaction is guaranteed as you witness improved performance, reduced downtime, and increased productivity in your operations. Upgrade to excellence today and reap the benefits for years to come. Contact us at +91-9099996851 or +91-9099996853 or email us at inquiry@anandseamless.com for expert consultation. We will be happy to assist you.

lATEST BLOG |

|

How to Choose Right Grade Carbon Steel Seamless Tubes

Carbon steel seamless tubes are essential componen |

|

Basics of Aluminum Finned Tubes

In the world of heat exchange technology, aluminiu |

|

How to Enhance Mechanical Tubes for Various Applications

Mechanical tubes form the backbone of various indu |

|

Why Are U-Tube Heat Exchangers Undeniably Vital: A Complete Guide

In the landscape of industrial heat exchange syste |

|

Introductory Guide to Economizer Tubes

In the dynamic landscape of industrial operations, |